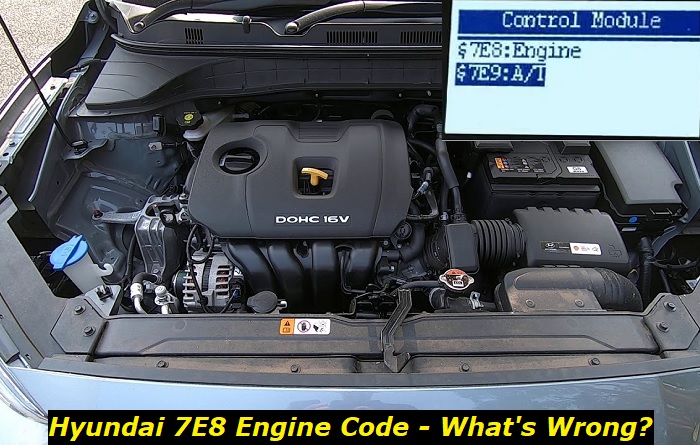

The 7E8 engine code in Hyundai can be triggered by various factors. Sometimes, it could be gone the next time you restart and drive your auto. However, when major problems in the Evaporative Emission Control System and/or other electrical components of your vehicle are present, it likely involves repairs or parts replacements that should be handled by a qualified technician or mechanic.

7E8 code highlights

- Level of urgency:Medium

- Possible culprits:Anykind ofproblems with engine management system

- Price for repair:$50 - $500

- If neglected:Engine limp mode, electrical issues, problems escalating

- DIY repairs:Possible but complicated

- Can you drive?Carefully

Primary Cause of the 7E8 Engine Code in Hyundai

According to various sources from Hyundai, reports, forums, mechanics, and vehicle owners who are familiar with the matter, the 7E8 engine code in Hyundai primarily points to a problem in the Evaporative Emission Control System. The most common reason for this is a leak in the evaporative canister.

Basically, the Evaporative Emission Control System is responsible for minimizing the emissions from the vehicle exhaust. It works by capturing fuel vapor that escapes when the engine is shut off, then stores it in a canister until it is ready to be used again or burned off during the normal operation of the vehicle.

When this system malfunctions, you may start noticing symptoms such as rough idling or stalling, poor acceleration, and fuel economy, as well as others. This can also trigger an error code like 7E8 in vehicles with onboard diagnostics (OBD) systems.

To diagnose the cause of this problem, mechanics usually begin by inspecting for any visible problems that could be causing a leak. The technician should check all hoses and connections leading to the evaporative canister for any cracks or breaks.

Next, they can do a manual test of the system by pressing down on each side of the evaporative canister and listening for any air escaping from it. If no leaks are found, then a smoke machine test or pressure test may be used to further confirm if there are any potential problems with the system.

Finally, if all these tests come back positive, the problem could likely be the result of worn-out components within the Evaporative Emission Control System. The parts that would need to be replaced include things like seals, valves, hoses, and more, depending on what is found during the evaluation.

In some cases, replacing just one component can fix up the entire system. However, in other cases, you may have to replace multiple parts to get the system back up and running. Therefore, it is important that you thoroughly inspect the evaporative canister and all its components so that you can pinpoint the source of the problem correctly. Once all this is done, the 7E8 engine code should be resolved and no longer be present in your vehicle.

It is highly recommended that you seek out a professional mechanic to diagnose and repair the problem. Doing so will help ensure that the same issue does not happen again in the future.

Other Factors Triggering the 7E8 Engine Code in Hyundai

While it's true that the 7E8 engine code in Hyundai directly suggests a problem in the Evaporative Emission Control System, other electrical components could also falsely trigger it. So, if you find the Evaporative Emission Control System of your car is working well yet you are still encountering the issue, here are the other factors that you should keep a lookout for:

1. Malfunctioning Sensor

The 7E8 engine code in Hyundai cars can be caused by a malfunctioning sensor in the Emission Control System. This can be due to several reasons, including age-related wear and tear, incorrect installation or adjustment of the part, excessive vibration of parts in the system, a poor electrical connection from the battery and other components, or defective wiring harnesses.

To find the source of this issue, start by checking for any visible damage to parts like coolant sensors, airflow meters, and turbochargers. Furthermore, with an OBDII scanner connected to the vehicle's computer system, it is also possible to access stored error codes that may indicate a problem with one of these sensors.

If a sensor has failed, then it will need to be replaced in order for the 7E8 code to be cleared, as well as any other related codes. In addition, if a fault is found with the wiring harnesses, then they should be inspected and repaired or replaced to ensure no further problems arise.

When replacing parts like sensors in the Emission Control System, it is important to ensure they are installed correctly and adjusted properly so that they function optimally. This can help prevent issues from arising in the future.

When dealing with this issue it is also important to check other components of the vehicle's emission system such as catalytic converters and exhaust pipes for any signs of damage or blockages which may have caused the fault code to be triggered. If any issues are found, then they should be addressed to prevent further problems from occurring.

Ultimately, it is important to properly diagnose and repair the 7E8 engine code in Hyundai cars so that the vehicle can continue operating safely and efficiently. By taking these steps, drivers can help ensure their car runs smoothly without any problems arising in the future due to a malfunctioning sensor in its Emission Control System.

2. Failing Battery or Alternator

Another cause of the 7E8 engine code is a failing battery or alternator. To properly diagnose this issue, it's important to understand the symptoms to look for, as well as any visual checks that can be done on the affected system components.

A common symptom of a failing battery or alternator is decreased performance from the vehicle overall-such as difficulty starting and slow acceleration. This can be accompanied by warning lights on the dashboard, including check engine lights and battery symbols which indicate low voltage in the electrical system.

When troubleshooting this issue, it's important to use a multimeter tool to test both the battery voltage and alternator output. A battery reading of 12.5 volts or lower, or an alternator output voltage below 13 volts is indicative of a failing alternator or battery respectively.

If the issue is found to be coming from either the battery or alternator within the Emission Control System, replacement parts will need to be purchased to fix the problem. It's recommended that a qualified mechanic installs these components for safety reasons and optimal performance.

Furthermore, it's important to remember that all other emission-related systems should also be inspected during this time to ensure no other faults are present which could cause further problems down the line.

3. Busted Fuse

The 7E8 engine code related to the Emission Control System of Hyundai cars can be because of a busted fuse, too. This could be due to numerous reasons, such as an electrical short-circuit or high voltage spike.

A visual inspection of the fuses should be done first before running any tests with diagnostic tools. The most common symptoms of a fuse going bad are signs of burns on the fuse itself, flashing lights on the dashboard, erratic idling, and failure to start in some cases.

Once a busted fuse has been identified, it must be replaced immediately else it will continue to cause problems with vehicle performance. To properly diagnose this issue, certain tools may need to be used such as voltmeters and ammeters.

Depending on the make and model of the car, different types of fuses may be required. It is essential to replace only those parts that are needed to avoid unnecessary fixes.

4. ECU Errors

A malfunctioning electronic control unit (ECU) can also erroneously trigger various fault codes in your engine, such as the 7E8 warning. At times, it can be due to a glitch in the software of your vehicle's onboard computers, associated modules, or the ECU hardware itself.

The most common symptom of a broken ECU is an illuminated engine management light on your dashboard. It's also likely that the car will produce less power and fuel economy than normal when experiencing such problems. Furthermore, you might notice decreased acceleration from the engine and other minor issues in your vehicle's performance.

When analyzing an ECU problem, it's highly recommended to begin visually inspecting all fuses for corrosion or blown-out coils before doing any further testing. If no physical damage is visible, use specialized automotive tools to identify if the voltage isn't being sent to the ECU.

Replacing any damaged components is a quick easy fix in this situation. However, it's important to note that replacing parts doesn't always solve the problem, as the issue may be with the software instead of the hardware.

If the problem persists, then you should consider having your ECU reflashed by a professional mechanic. This means they will install new software updates or repair existing ones.

If reflashing fails to resolve problems, then a replacement of your vehicle's ECU might be necessary, especially when its hardware is already battered by age. Although due to its costliness, many tend to avoid this option unless absolutely necessary.

Conclusion

The 7E8 engine code in Hyundai can be triggered by various factors. It ranges from a simple glitch in the system that can be gone the next time you restart and drive your car. However, in more serious scenarios, it could mean repairs or parts replacement.

Regardless of the reason for the code, it's important that you should address it as soon as possible with the help of your trusted automotive technician or mechanic.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment