To begin with, a quick check on your car badge can give an idea of whether your car is turbocharged or not. Normally, the letter 'T' together with other letters that come after your car name or engine denotes your engine is turbocharged (for example TDI, or TDCI)

Engine upgrades highlights

- Commonsystems:fuel supply, air supply, exhaust, software

- Average prices:$500 - $6,500

- Average waiting time:1 - 21 days

- Commonreasons:higher power and torque

- DIY mods:just minor things, usually plug & play

- Level of satisfaction:medium

How the turbo works

A turbocharger pumps extra-compressed air into the engine to increase combustion which raises the power output of the engine. The device uses exhaust gases to compress air intake and force it into the combustion chamber. The turbo extracts exhaust gases which are then used to drive the compressor and force extra air into the combustion chamber compared to normal engine intakes.

Air Induction

This hot air induction proportionately influences more fuel injection into the chamber, leading to enhanced combustion. The enhanced combustion releases more automotive power which results in a more powerful and faster vehicle. A turbo-charge enhances all major engine parameters including power output, fuel economy, and emissions that routinely influence vehicle performance.

The principle of the internal combustion engine is very simple. A mixture of air and fuel is ignited in the engine cylinders to produce an explosion that drives the engine pistons up and down. This explosion is what drives your car. Increasing one of these parameters increases the magnitude of the explosion resulting in more engine power.

Increasing fuel intake in the combustion chamber would be uneconomical. Thus, a turbocharger increases airflow (air is free) which then raises the engine power output without compromising on fuel economy.

A turbocharger device has a compressor and a turbine that compresses and pumps air into the combustion chambers of the engine. The device boosts air intake into the engine to increase the capacity of each combustion strike, thus producing more engine power. At almost the same amount of fuel and cost. The turbocharger makes the engine more efficient and easy to achieve optimum fuel economy in a 'small' engine and an energy output of a 'big' engine.

Turbochargers do not require additional plugging into the engine to operate. Instead, it harnesses the exhaust gases to operate the device and push more air into the cylinders. The exhaust gases are channeled to the device and due to their high pressure, turn the turbo fans which draw in more air into the compressor. The compressed air is then forced into the engine combustion chambers under great pressure.

Either, a turbocharger does not require to be switched on and it is not always on. It gets automatically activated when the engine reaches a certain speed. This is because it is the exhaust gas energy that will switch on the turbo fans after reaching a certain pressure.

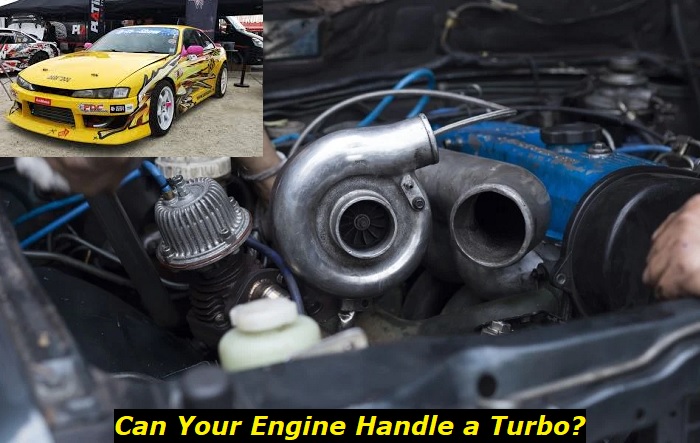

Can you fix a turbo in any engine?

Since a turbocharger is an 'air pump' that increases airflow into the engine cylinders, a turbo can be fixed in almost all engines provided the required devices can fit in your engine. Non-turbo engines- naturally aspirated engines use the normal atmospheric air and flow to complete the combustion cycle in the cylinders.

Fixing a turbocharger on a naturally aspirated engine will require more than just fitting the device into the car. It comes with a host of other modifications that must be carried out to fine-tune your turbo system with the non-turbo engine. The modifications arise from the fact that the NASP engine operates differently from the turbo engine in terms of the air intake, compression ratio, fuel injection, cooling process, and waste gases system.

A turbocharger modifies the airflow system by pumping compressed air which significantly increases the horsepower output of your engine. The additional compressed air requires a proportional fuel injection to efficiently release the extra turbo power that drives your engine.

However, adding a turbocharger device is not enough. Some modifications are required to ensure the new airflow system works harmoniously with the existing combustion system. Modifying a naturally aspirated engine into a turbo-charged one requires several considerations to avoid destroying the engine.

If these modifications are not done the engine may not handle the extra stress that comes with turbocharging.

1) Compression Ratio

Compression ratio refers to the amount of air that an engine rolls up ready for the firing phase. A normal engine's compression ratio cannot be effective when a turbocharger is fitted. When modifying your engine into a turbocharged one, the compression ratio in the naturally aspirated engine must be modified. This is done by fitting a decompression plate between the cylinder head and the engine block.

Another way to reduce the compression ratio to cope with the added turbocharger is by using low/short compression pistons which decrease the stroke or re-boring the engine to increase the cylinder capacity. If this modification is not done, the turbocharger might result in massive compression which the engine may not be able to handle, causing severe damage to your engine.

2) Exhaust Modification

The turbocharger highly depends on the exhaust gases to operate. Thus, the exhaust system in your car must be modified and upgraded to allow the exhaust gases to be channeled to the turbocharger device. If this is not done, the existing exhaust system may be below what is required to activate the turbo.

3) ECU

The ECU will require modification and tuning so that it can sense the new engine firing system which has more compression than before. Sometimes, it may be difficult to tune the ECU and in such a case, a new ECU must be installed to be in line with the new engine system. Thus, upon adding new after-market parts to work with the turbocharger, the ECU must be reprogrammed to put it in line with the new engine specifications.

4) Cooling System

When a turbocharger is fitted, the engine will operate at very high temperatures and pressure. Thus, the engine cooling system must be modified to include a combination of an intercooler and an oil cooling system. The intercooler system cools down the hot air from the turbo while the oil cooler regulates the turbo lubricant to ensure it does not overheat. Failure to carry out these modifications correctly will lead to overheating problems for your engine.

5) Performance injectors

The fuel pump and injectors need to be changed so that they can feed enough fuel commensurate with the increased airflow in the combustion chamber. Fuel injectors deliver fuel in form of a fine gasoline mist in the combustion chamber. However, with an aftermarket turbocharger, the injectors cannot keep up with the increased air intake. This calls for a change to performance injectors which deliver more fuel to be burnt by the extra air flowing from the turbo.

Thus, you will require a new set of performance injectors and a performance fuel pump which should match your specific engine. Moreover, you should carry out some calculations to map out the required engine output to purchase the right injectors. If the injectors spray too much fuel, the engine will have an output that is as low as that from injectors spraying too little fuel into the combustion chamber.

6) Change the crankshaft

The performance as well as the power output of your engine very much depends on the design of the crankshaft. The pistons' angle, firing order, and engine configuration are generally based on the crank design. When fitting an after-market turbocharger, upgrading the crankshaft will go a long way in reducing the compression ratio to increase power output.

A long or short throw crankshaft alters engine volume by decreasing the piston stroke. The crankshaft can also be made lighter to get a performance boost. Lighter weights and counterweights in the crankshaft mean more engine power output as it responds more quickly to power shifts.

Conclusion

There are many more considerations to make if you want to achieve high performance from your turbo conversion. From fuel flow and spark timing to ignition timing control, one has to carry out a myriad of modifications and re-modeling to achieve the desired turbo output from a NASP engine. The most critical change is that of controlling fuel input and compression ratio in the combustion chambers to acquire the power output and efficiency of the turbocharger.

Adding more horsepower to your car through an aftermarket turbocharger may not be as easy as it may look. If you can get everything right, you will end up with extra power from your engine, but it comes at a cost.

It should not escape your mind that small turbocharger units with low boost levels are the best to fit since they do not require massive and expensive remodeling.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment