When you interact with owners of RAM made before 2019, you will not help but hear a gloat when they start talking about the fuel pump in their trucks. At the same time, when you meet up with a 2020 RAM truck owner, you will certainly hear a cry of frustration and see an almost sad smile when they tell you about the new CP4 injection pump introduced in 2019.

Fuel supply problems highlights

- Level of importance:Very high

- Can you drive?Usually, no

- DIY inspection:Possible

- DIY repairs:Mostly,impossible

- Price of repair:$300 - $650

- Commonreasons:Fuel pump, fuel filter, fuel lines, EVAP system, electrical problems

- How to fix:Check the pump, verify it has power, check the fuelfilter

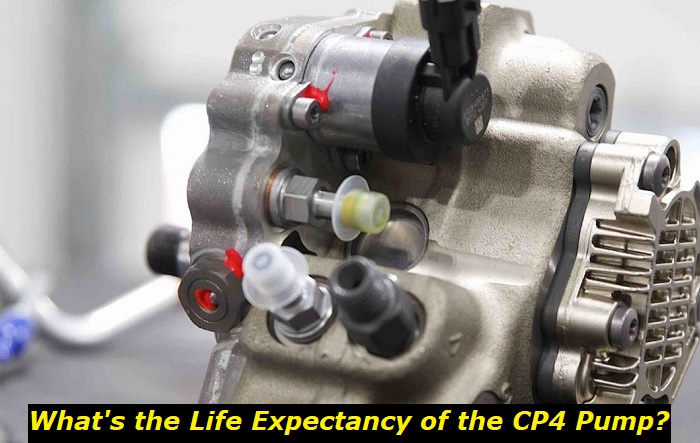

What is a CP4 pump?

The CP4 is a high-pressure fuel pump found on American trucks such as the RAM 6.7L and Ford 6.7L Powerstroke. The CP4 was an upgrade of the CP3 pump that had been in the market for close to 10 years. The CP4 pump is designed to deliver fuel into the connected rail system under immense pressure.

The CP4 can be categorized into two: the CP4.1 and CP4.2. The CP4.1 has a single element commonly used on smaller diesel engines. The CP4.2 comes with two elements and is used on bigger engines. When we talk of CP4 problems, we refer to both of the above variants.

Each of these elements found in the pump comes with its own camshaft. Inside the pump, there are chains, cogwheels, and belts that are used to drive the camshaft. These moving components are critical in moving the pump pistons to allow the pump to generate the immense pressure required to keep the engine running.

For the longest time, Bosch has been manufacturing parts used by various industries. GM and Cummins have had a long relationship with Bosch, where the latter supplies the former with diesel injection pumps. In 2001, GM picked the now very popular CP3 diesel injection pump for use on its LB7 Duramax truck. Two years later, the Cummins engine installed in Dodge RAMs carried the same pump.

While every carmaker tweaked their own CP3 to suit their vehicle needs, it has been a general consensus that a CP3 pump can last up to half a million years. Following the unrivaled success of the CP3 pump, Bosch introduced the supposed successor, the CP4 pump. GM and Ford quickly took up the new pump, which was used on the Ford 6.7L Powerstroke and GM Duramax 6.6 LML/LGH starting in 2011. RAM came a little bit late in 2014 with the Jeep 3.0 and RAM 6.7L Diesel in 2019.

The CP4 pump has its fair share of problems, many of which are serious. But the advantages that come with using this pump are not to be overlooked. This pump easily helps carmakers achieve government emissions regulations. Unlike the CP3, the CP4 pump with a higher psi rating will provide ample fuel at the right pressure even when the engine is above 3,000 RPM. This means the CP4 pump engine runs cleaner than the CP3 one.

Life expectancy of the CP4 pump

According to Bosch, over 60 million CP4 pumps have been sold worldwide since its launch. While these pumps are used in a wide range of applications on the road and in industrial settings, it's easy to note the pump's tenacity.

But like every other product or service in the market, the life expectancy of the CP4 pump relies on customer satisfaction and market share. RAM sells a large number of its 6.6 L diesel trucks in North America. Almost immediately after introducing the CP4 pumps in its magnificent truck, the company receded its decision and reverted to using CP3.

The best pump to compare the CP4 to is the CP3. Unlike the CP3, which affords the driver numerous warnings and faulty symptoms, the CP4 tends to simply die on you in the middle of the road. You will need a tow truck, and in addition to that, you will spend anything between $7,000 and $10,000, depending on the severity of the damage.

The CP4 pump has been giving GM and Ford buyers problems since 2001, or just a few months after its launch. In 2019, the same story was repeated when new RAM 6.7L owners furiously complained about the unreliable injector pump.

The powertrain warranty also covers the CP4 pump in your vehicle. In the case of the RAM 6.7L truck, the warranty is 100,000 miles, which means the CP4 is covered for quite a distance. Many RAM, Ford, and GM vehicles are equipped with this pump and have never developed a fuel injection pump problem. Given proper care, the CP4 has been seen to surpass the 300,000-mile mark.

What are the reasons behind the CP4 problems?

The CP4 is designed to work like every other injection pump you know. It takes diesel from the fuel lines, pressurizes it, and feeds it to the rails. At the right moment, the engine piston is on its compression stroke just before the piston head reaches the top dead center. But the way it works is what makes the CP4 rather sensitive.

1) Poor lubricity

This problem is closely related to the ultra-low sulfur diesel (ULSD) that has been in the market in the past few years. The design of CP4 means it requires to be lubricated constantly and as you may know, low-sulfur diesel doesn't offer good lubrication for this pump.

The low lubrication in the CP4 pump means that the many fast-moving components inside will have a difficult time functioning. The increased friction of the metal moving parts, such as the camshaft and the lifters in the pump, means metal shavings will start being emitted by the pump alongside the highly pressurized fuel. As the metal shavings continue to spread throughout the fuel system, one can only expect disastrous results eventually.

2) Air bubbles in the pump

When the CP4 pump continues to struggle to pump fuel into the common rail due to the increasing friction between the internal moving parts, air bubbles tend to form. The presence of air bubbles in the pump housing is a strong indicator that the metal parts are moving against each other with little lubrication.

Presence of air in the injection pump can cause the fuel system to have an airlock. The resulting effect of an airlock is hesitation of the vehicle, especially when you step on the gas pedal. The air can also cause the engine to misfire. You may also notice poor fuel economy and rough running of the engine.

3) Roller Lifter turning sideways

This problem is closely related to metal parts inside the pump rubbing against each other. As the parts move with friction against each other, the lifter starts to cut into the camshaft instead of riding on it. They will turn or spin 90 degrees, and this simply means the end of the pump and damage to many other components.

4) Water and poor fuel quality

The CP4 injection pump is a rather sensitive pump. While it helps car manufacturers meet and surpass the government cleaner air regulations, its sensitivity makes it prone to problems. The fuel sold in gas stations in the USA and surrounding countries contains impurities. The best diesel in the market will be found in petrol stations across Europe.

When there are impurities in the fuel, lubrication of the moving parts inside the CP4 pump gets compromised. As highlighted earlier, low lubrication fuel is problematic for this pump. On the same topic of impurities, we have to mention that water is one of the contaminants found in diesel. Any contact of water with the CP4 pump means bad things will follow. Water magnifies the non-lubrication problem, and you may very well lose the pump and other vital parts because of a little water.

What to do to avoid the problems

The first thing to do to prevent the CP4 seemingly inherent problems is;

- Supply a constant supply of clean diesel.

- Always change fuel filters on schedule and, where possible, before schedule. This helps to trap any metal shavings that might have been captured by the filter.

- Add some lubrication into the fuel system. It's poured into the tank with every fill-up.

- You can change the pump to CP3.

Conclusion

The CP4 pump has its advantages which make it stand out. After reading this article, you may feel like you don't have a lot of wiggle room if you own a vehicle with a CP4 pump. However, by noting the specific problems affecting this pump and ways one can prevent or mitigate them, you are likely to enjoy your truck without much drama for many miles.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment