Fuel injectors have come a long way in vehicles since they were introduced commercially in the mid-1900s. They served as a replacement for the older Carburetor in vehicles and are very important in fuel distribution. In a vehicle, it is important to maintain an accurate fuel-to-air ratio and this is what a fuel injector perfects.

Fuel supply problems highlights

- DIY repairs:very complicated

- Tools needed:pro electrician's tools

- Commonreasons:power supply, electric units issues

- Time to repair:3 - 5 hours

- Price for parts:$150 - $600

- Can you drive?No

- Alternative solutions:no solution but repairing the problem

What are Fuel Injectors?

Fuel Injectors were developed as an improvement to carburetors in vehicles. One of the purposes of this is to manage the fuel-to-air ratio. For an engine to operate smoothly and efficiently, the introduction of fuel must be regulated. This regulation is carried out by the fuel injector.

Regulating the fuel involves carefully maintaining the ratio of fuel and air introduced into the engine. In earlier times, this function was handled by carburetors, but even with a twin carburetor, perfection is not easily achieved. Hence, the introduction of fuel-injected vehicles to control the rate of fuel to air in vehicle engines.

How Fuel Injectors Works

A fuel injector is a solenoid valve; a valve that is used for controlling liquid or gas flow. Fuel injectors are of two types, the first is Electronic Fuel Injection and secondly, Mechanical fuel Injection.

The difference between the two types is majorly in the factor that controls the increase or decrease of releasing fuel. In mechanical fuel injection, fuel is controlled by a mechanical regulator assembly and it is being replaced by EFI. EFI, short for electronic fuel injection is controlled electromagnetically.

While both are spring-loaded into a closed position, they are controlled differently. Also, EFI is more efficient and has in time become a better replacement.

Fuel injectors regulate the fuel delivery to the combustion chamber, making sure that the required quantity is injected at the appropriate time. The procedure is as follows:

- The fuel pump delivers petrol or diesel to the injectors via the fuel lines.

- The engine control unit (ECU) determines when to control the injectors to release fuel into the combustion chamber by spraying.

- Pressurized fuel is squirted through valves into the combustion chamber when the ECU fires up the injector. Due to the small size of the valves, the fuel is easily vaporized, resulting in a more efficient burn.

In a mechanical fuel injector, instead of the ECU sensors, there is a mechanical fuel pressure that controls fuel spray.

How to detect a Faulty Fuel Injector

Signs of a Faulty Fuel Injector Problem and Repairs

There are several ways to troubleshoot a vehicle's injector problem, three of these ways are described below.

Engine Misfires: One of the easily noticed symptoms of a fuel injector error in a vehicle is engine misfire. When an injector is clogged or malfunctioning, the vehicle will experience a delay in acceleration. In such situations, it is correct to conclude that the fuel injector is not delivering the expected fuel dose. This can be majorly avoided by cleaning the injector of any clog or blockage.

A misfiring engine will appear shaky, this problem may be caused by a fault in the wiring of the Injector harness. The best step to take in this situation is to access the wiring of your Fuel injector. If any tear or wiring exposure is found, you should order a new harness and replace it.

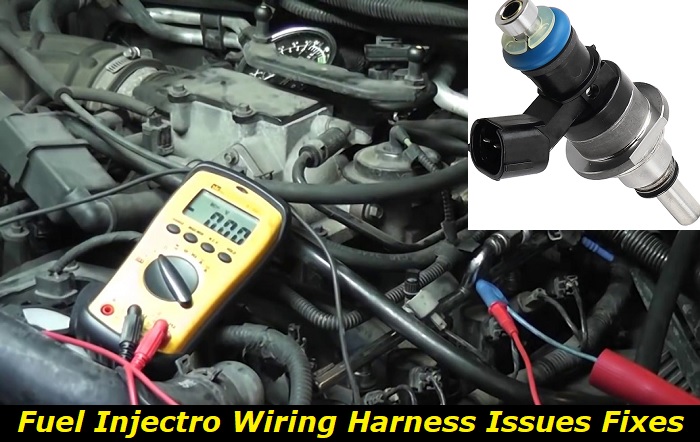

Incorrect voltage delivery: Like the situation in fuel-to-air delivery, it is important to have the right voltage delivery. A faulty fuel injector can affect the stability of your vehicle as well as fuel usage. The easiest means of checking the voltage delivery is using a Multimeter. Using a multimeter will help in troubleshooting the wiring system of your vehicle's fuel injector harness.

Rough Idling: Ever noticed your vehicle is unstable at a stop light? Then you might be facing a Fuel injector problem. When your vehicle does not go into idleness stably and becomes unstable when placed to rest, it needs troubleshooting.

In such a vehicle, there's noticeable engine noise when idle. However, this is not peculiar to fuel injector issues. This problem may also be a sign of a dirty air filter or a bad plug. Anyways, when you notice this problem, you should pay a visit to the local mechanic.

Poor fuel economy: The primary function of a fuel injector is to maintain a stable ratio between the fuel and air entering the engine. A bad injector will therefore not manage the fuel properly and lead to poor fuel economy.

A leaky or clogged injector can also be the cause of poor fuel economy. The effect of this problem is usually significant on the performance of the vehicle.

Fuel Leakage: Fuel leakage is another symptom of a possible fuel injector fault. This is noticeable when you smell fuel strongly while driving. Fuel leaks are usually a sign that your injector needs to be changed. It is very common in old injectors.

Poor maintenance can also lead to fuel leakage. This can be examined without hassle as there will be considerable fuel spilled around the injector.

Warning Light: For most vehicles, once there's an issue with the engine, the engine warning light comes on. This can also be a signal to check your Fuel injector. Even though it may not be the cause of your error, an engine warning light can be a sign of a faulty fuel injector.

Testing your fuel Injector with a Multimeter

Part 1: Testing Injector Resistance

Your main requirement for this test is a Multimeter with ohms setting but can substitute a digital Volt-Ohmmeter if available.

- To begin the test, ensure that your ignition is turned off, no power is required.

- Remove the injector wiring harness. This may require sliding a lock open in some cases

- Set the multimeter to measure ohms. If the instrument does not auto-range, set it to the least range.

- Test harness resistance using the multimeter or DVOM. To start, connect the meter wire with the prongs inside the connector. During this process, ensure that the different wires are not in contact.

- If your injector belongs to the high impedance category, which is the common type, you should have a resistance range between 12 to 17 ohms. Otherwise, you should have between 2 to 5 ohms for low-impedance injectors.

- Repeat the steps for all injector modules. You should get outputs within range of one another. Any odd reading is a sign of an issue in the wiring of the fuel injector. If you're unsure about the correct resistance level of your vehicle, you should search online or check your vehicle's guide

Part 2: Testing Injector Wiring

Unlike the previous part, this requires the ignition to be active for troubleshooting. The following are steps to take when testing your fuel injector wiring for faults.

- Turn the vehicle's ignition to ON but do not kickstart the engine, just get the battery flowing.

- Set your Multimeter/Ohmmeter to read in DC voltage. If the meter does not auto-range, select the lowest range possible.

- Next is to ground the negative lead on the meter by connecting it to a ground source. If your equipment has a clip, use it to hold the lead in place. You can use the car frame to ground the meter (use an unpainted side).

- With the negative lead hooked and grounded, you can freely attach the positive lead to the wiring harness terminal. The wiring harness has two parts; one is grounded and has a volt charge of 0. The other is charged and should have a value of 12 volts.

- Repeat these steps on the other harness terminals and monitor the difference in volts. Low reading in any of the terminals means there is high resistance in the wiring somewhere. A higher reading means there is low resistance in the fuel injector wiring harness.

This electrical test is not always perfect for finding the issues with a fuel injector. Hence, further tests may be required to confirm the issue with your vehicle.

Final Words

The easiest way to maintain your Fuel injector against wiring harness problems is to ensure adequate cleaning. As a car owner, having a fuel system cleaner can be the best thing for your fuel injector. While it doesn't make them last forever, it improves performance and clears the injector of any blockage.

If you're unfamiliar with the processes of testing your fuel injector and suspect it may be the fault, take a visit to the local mechanic. While this may seem to cost more than DIY, it is worth getting a professional's opinion.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment