The transmission system ensures the proper delivery and distribution of power coming from the engine of a vehicle. This makes it a very critical component of an auto that needs to be in good working order all the time.

Transmission repair highlights

- Level of importance:High

- Time interval:When broken

- Needed expertise:High

- Needed tools:Professional set of tools

- Time taken:2-20 hours

- Possible issues:Transmission not shifting, gearbox freaking out, car may be in limp mode.

How the Flexplate Works

The flexplate is an important component of a vehicle's powertrain. It functions as a vital link between the engine and transmission, transferring the torque from the crankshaft to the transmission. The flexplate has teeth that mesh with those on the torque converter, allowing it to rotate at different speeds while still providing enough traction for power transfer.

In addition, it acts as a buffer between the engine and transmission, dampening vibration and noise. This helps ensure smoother operation and increased longevity for both components. Without a properly functioning flexplate, vehicles would experience poor performance due to insufficient power being transferred from the engine to the transmission. Therefore, it's important to keep it under ideal calibrations and ensure that any signs of damage or wear be addressed promptly to avoid costly repairs or replacement later on.

How the Torque Converter Works

The torque converter is another essential part of any vehicle. It plays a key role in transferring the power from the engine to the transmission, allowing a smooth and efficient transition from one gear to another. It works by using hydraulic fluid to create a rotating flow that connects the engine and transmission, thus providing a cushion between them. This cushion allows for smoother shifts and improved fuel economy.

The torque converter also plays a vital role in reducing wear on the internal components of a vehicle's transmission system. By absorbing some of the load imposed on those components during acceleration or deceleration, it helps prevent premature wear and tear.

In order to keep it functioning properly, periodic maintenance should be done on this part of the auto. This includes checking oil levels and draining off any accumulated dirt and debris at regular intervals. Proper maintenance of the torque converter is essential in ensuring a long, trouble-free life for any vehicle.

Why Should There Be an Adequate Spacing Between the Flexplate and the Torque Converter?

A good gap between the flexplate and the torque converter should be maintained at all times. Failure to do so could lead to the following scenarios:

1. May Result in the Transmission Not Engaging Properly

If the gap between the flexplate and torque converter is too small, then the transmission may not be able to engage properly when shifting gears. This can lead to grinding or slipping of the gears, as well as excessive vibration and wear on both components.

2. May Dramatically Increase Friction in the Transmission

If there is not enough space for proper lubrication, then the moving parts of the transmission will experience increased friction and heat build-up. Without adequate lubrication, these parts could become overworked or even seize up due to high temperatures and prolonged use.

3. May Lead to Imbalanced Power Delivery

A bad gap between the flexplate and torque converter may also cause an imbalance in power delivery from the engine to the drive wheels. Such an unbalanced setup could lead to premature wear and tear of the drivetrain components, as well as an inconsistent performance from the vehicle.

4. May Cause Plenty of Noises

Too much clearance between the flexplate and torque converter can cause excessive noise from the transmission due to a lack of stability in the connection. This can make driving uncomfortable or even dangerous if it becomes too loud or severe.

5. May Result in Misalignment of Drivetrain Parts

Having a bad gap between the two can also cause misalignment of the parts, which could lead to further damage to other components in the drivetrain system due to increased stress on them caused by misalignment. This could eventually lead to major problems with your vehicle's performance and reliability.

6. May Negatively Affect the Engine

The resulting transmission issue brought about by the incorrect spacing of the flexplate and the torque converter can eventually put a lot of tension on the engine. It can lead to higher RPMs, hinder performance, or trigger fault codes related to the power unit and transmission that may force your vehicle to go into "limp mode".

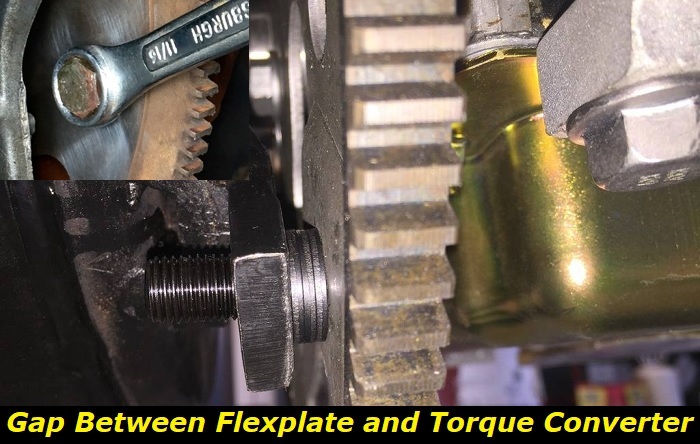

The Ideal Spacing Between the Flexplate and the Torque Converter

The flexplate, which is found between the engine and the torque converter, must be installed with a gap that is at least 1/8 of an inch and no more than 3/16 of an inch. This is due to the large amount of torque generated by the engine, which can cause excessive vibration in the transmission system if it is not properly spaced.

As mentioned earlier, the flexplate acts as a buffer for this vibration and must be tightly secured against the torque converter to provide adequate protection. Having too much or too little space between them will allow the components to vibrate excessively, leading to premature failure of other transmission components and potentially even damaging internal components such as bearings and seals.

Another important reason for maintaining appropriate spacing between these two components is that the flexplate and torque converter must be in proper alignment for efficient operation. If there is too much space between them, their rotational axes will not line up properly, causing a decrease in fuel efficiency and even an increase in emissions from the vehicle.

Maintaining the said gap keeps the components properly aligned, providing optimal transmission performance as well as increased fuel economy, lower emissions, and reduced engine stress.

How to Effectively and Safely Calibrate the Spacing Between the Flexplate and Torque Converter

There are certain steps that you can follow to accurately calibrate the gap between the flexplate and the torque converter if you think that they are not spaced properly.

1. Measure the Current Gap

Start by measuring the current gap between the flexplate and torque converter. Ideally, it should be in the range of 1/8 to 3/16 of an inch mentioned earlier.

2. Adjust as Needed

Use a feeler gauge to adjust the spacing as needed until you achieve the desired measurement range.

3. Retighten Bolts

After adjusting the spacing, retighten all mounting bolts so that they are securely attached and ensure that they're properly torqued according to manufacturer specifications.

4. Re-measure

Once everything is tightened down, re-measure the gap again to ensure that it is still within acceptable ranges.

5. Drive Around the Neighborhood

After ensuring that you have calibrated the parts as you see fit, test drive your vehicle and pay attention to any noise or any unusual vibrations coming from the areas of the flexplate and torque converter as well as how your transmission works. If everything checks out well, then you're done.

Remedies If Spacing Is Not Within Ideal Settings

If the flexplate and torque converter spacing are not within their ideal setting after following the steps above or you notice anything unusual as soon as you drive your auto, then it is likely that other issues with your transmission system may be present. It is recommended to contact a professional mechanic who can properly diagnose any potential problems and help you safely resolve them.

Additionally, an experienced technician should always be consulted if you have any doubts or questions regarding the installation of the flexplate or its spacing with regard to the torque converter. A qualified technician can provide valuable guidance on how to properly install and maintain this component for optimal performance.

Factors that May Affect the Spacing Between the Flexplate and Torque Converter

Take note that there are certain conditions that may cause the misalignment or inaccurate spacing of your flexplate and torque converter. These include the following:

- Loose or improperly torqued mounting bolts

- Damage to the flexplate or other transmission components

- Excessive engine vibration

- Worn-out drivetrain parts

- Frequently driving on rough terrains

- Vehicle collision

- Overheating especially in the transmission area

It is important to remember that these factors can cause changes in the gap between the two components. Hence, it is essential to inspect your transmission regularly and ensure that all of its parts are in good condition as well as properly adjusted for optimal performance.

Conclusion

To sum it all up, maintaining proper spacing between the flexplate and torque converter is essential for ensuring efficient transmission performance as well as protecting internal components from premature wear and tear. Following the steps outlined above, you can easily and safely calibrate the spacing between these two components in your vehicle.

If you have any doubts or you find that the gap is not within its ideal setting post-calibration, we strongly recommend contacting a professional technician or mechanic for further advice. With their help, you can ensure optimal performance and avoid any potential damage to other transmission components. This will help keep your vehicle running smoothly and reliably for years to come.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment