Almost all gas-powered cars now come with a special feature in their engines. The timing of the valves can be adjusted according to road conditions, RPM, engine load, etc. The systems that help the engine adjust its valve timing are completely different. But the most common system uses the so-called VVT solenoids (variable valve timing solenoids).

Camshaft problems highlights

- Level of importance:Medium

- Commonreasons:Variable valve timing actuator problems, cam bearings issues, overheating

- DIY inspection:Possible but complicated

- DIY repair:Impossible

- Price for repair:$350 - $850

- Can you drive?Usually, yes

- Ways to fix:Clean the VVT (VCT) solenoids, inspect the camshaft, clean the valves

What are those nasty VVT solenoids?

These are the kind of actuators that control the oil flow and help valves stay open longer if needed. The work of the solenoids depends much on the type of the engine and on some other technologies used in it. In short, they may be open or closed depending on the conditions and they regulate the flow of oil in the VVT system.

In most cars, these solenoids will work just well up to 100,000 miles if the engine is maintained properly and regularly. After that, they may fail and a lot of repair shops will say your vehicle needs replacement solenoids to get back to life. But you may have heard that people clean those parts and they keep working well. Let's see if this is possible.

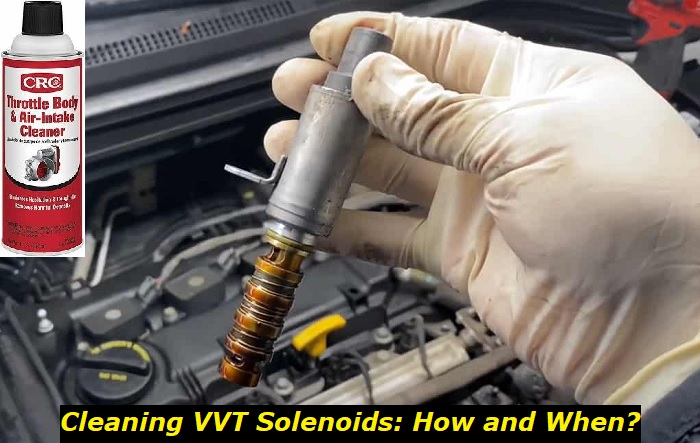

How to clean VVT solenoids when they fail?

First of all, you should know that the symptoms of bad VVT solenoids are pretty common for other types of engine problems and you should diagnose the engine first before you take those VVT parts off the vehicle and try to do anything with them.

If you are sure the problem is in solenoids, you can prepare for cleaning them. First, make sure you have the following tools and materials:

- some basic tools to take the solenoids off the engine;

- clean gasoline or WD-40 to clean the parts;

- clean engine oil (the oil that is used in your engine is recommended);

- two cups to make the cleaning process easier for you;

- a battery (a car battery or just any battery that has two terminals you can connect to);

- a couple of cables you can use to connect your solenoid to the battery.

Well, if you have all these things, you are ready to start. Locate your VVT solenoids. Usually, they are placed in the front part of the engine, just near the valve cover (under it, mainly). You may need to take some plastic covers off the engine to get access to solenoids.

First, take the electrical connection off the solenoid. Then you have the access to the bolt or bolts that hold the solenoid in place. Use the appropriate wrench to unscrew the bolts in all solenoids. This may be challenging to pull solenoids out of the engine - you may need some pliers or other tools to help you do that.

Once you have old solenoids in your hands, you should do the following to clean them:

- pour some clean gasoline into a cup or you can skip this if you are using other cleaners like throttle body cleaner or WD-40 (not recommended though);

- connect your solenoid to the battery and leave one connection free to play with the electrical supply to the solenoid;

- put the working part of the solenoid into the cup with gasoline or spray the cleaner on the solenoid;

- at the same time, intermittently send some current to the solenoid to make it open and close;

- do this for a minute and see if the solenoid started clicking louder;

- after that let the solenoid dry a little and then pour clean engine oil into another cup;

- put the working part of the solenoid into the cup with oil and activate the solenoid by connecting it to the cables you have used before;

- after 20-30 seconds your solenoid should be just fine.

Repeat this procedure with all VVT solenoids you have in your vehicle. This will help you make sure that all solenoids are OK and won't fail. After that, you will want to install them back into your engine. Make sure you fasten them correctly and put all the electrical connections back in the needed places. Then you will need to start the engine and check if the problems you've noticed before are gone.

Of course, you should also listen to the sound each solenoid produces in the end. If it doesn't click at all or clicks too weakly, chances are that your VVT solenoid is dying or dead. In this case, you may just buy another solenoid and install the new one instead of the broken one.

Why are VVT solenoids get clogged?

Solenoids basically let some oil through them and they have pretty tiny passageways for this. When your oil is a little dirty or has a too high level of viscosity, solenoids may get clogged or just don't get enough oil for proper work. Also, in older engines, the oil just can't be clean enough to let VVT solenoids work properly. They often get clogged with little particles, debris, or just with some viscose oil.

Also, VVT solenoids are not eternal and they may just fail after some time. In this case, cleaning will not help much and you will have to replace failed solenoids to let the engine work efficiently again.

To avoid this problem, change the oil even more often than the manufacturer requires and keep an eye on the quality of the oil. Also, oil filters should be changed every time you change the oil.

What are the primary signs showing that your solenoids need cleaning?

Depending on the level of clogging, the symptoms may be quite mild or severe. Once you notice one or several of these signs, you should clean the solenoids or at least diagnose the engine and find the problem.

Here are the most common signs that VVT solenoids aren't working properly:

- the engine works roughly at idle, RPM isn't stable;

- gas mileage is deteriorating;

- engine performance is not great, the acceleration is slower than usual;

- check engine light may go on in most vehicles.

These symptoms are not specific and may also mean a lot of other possible problems. But checking up the solenoids is a good idea before getting deeper into the engine. Also, most solenoids will work well up to 100,000 miles but they will likely fail after that. Sometimes, cleaning may prolong their life and let them work for another 10K miles or so.

If you've noticed that the oil in your engine is contaminated, you may be sure that VVT solenoids are suffering right now and will soon start showing all those symptoms.

Is cleaning VVT solenoids worth your time?

People keep asking us whether it's a good idea to clean VVT solenoids or if they should just let professional mechanics do the job. If you are perfectly sure that one of the solenoids is in charge of poor engine work, it's always worth checking this out and cleaning it. Also, cleaning VVT solenoids may be a good idea if they have already managed to go about 100,000 miles and have started showing the first signs of clogging.

But if you have no idea how to take them off the engine and don't understand our guidelines on how to clean them, better stay away from your engine - you may easily break something and will eventually spend much more money to have that repaired.

We don't see any reason in cleaning solenoids in such cases:

- your solenoids are older than 12 years and/or have made more than 150,000 miles - just replace them in this situation;

- the solenoids don't respond at all when you connect them directly to the car battery - you don't hear any clicks and this means they are burned;

- the solenoids are damaged or corroded - installing them back into your engine is not a wise idea, better replace them with a new one;

- the engine has other problems that add different symptoms - first repair the engine and then see if the VVT solenoids need cleaning;

- you don't have the appropriate place for doing this - in this case, better let professionals do the job for you.

Cleaning and replacing VVT solenoids will cost you more or less the same in a repair shop. Dealers will charge about $100 for each solenoid while other repair shops will take $50 or something for each solenoid. So, you can obviously try doing this by yourself if you have the proper place and at least some experience in unscrewing bolts.

But you should be careful. One mistake may bring very unpleasant consequences.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment