Relieving fuel pressure can be an effective way to diagnose and address a variety of engine issues without having to start the vehicle. In some cases, triggering the fuel pump relay manually will force fuel into combustion chambers that are not getting enough fuel on their own. This process can help identify clogged injectors or lines, which is especially useful if you have recently changed fuel filters.

Additionally, relieving the fuel pressure on a vehicle that has been sitting for a long time can help reduce the risk of backfiring and stalling due to deteriorated fuel in the injectors or lines.

This is also beneficial if you are performing maintenance on the engine, such as replacing spark plugs as it will give you peace of mind knowing that there is no residual pressure in the system prior to beginning your work. Ultimately, relieving fuel pressure can save time and money by helping identify problems quickly and efficiently, without having to start the vehicle unnecessarily.

Things You Need Before Relieving the Fuel Pressure in the System of Your Vehicle

Before performing the different methods that will be provided here, it is important to be properly equipped to ensure your working efficiency and safety. The following tools and supplies are necessary to achieve the desired results:

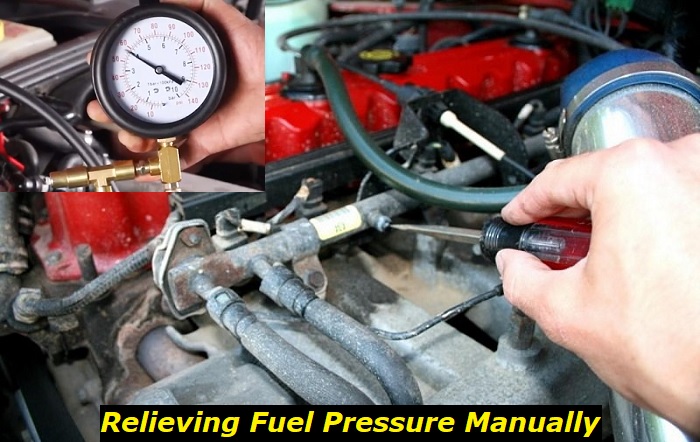

- A pressure gauge for gauging the fuel pressure in the system.

- An adjustable wrench or socket set to loosen any clamps or connectors that may need to be disconnected during the procedure.

- A screwdriver to remove any covers on your vehicle's engine compartment.

- Rags or towels, which can help contain any spilled fuel while working with hoses and lines.

- Safety glasses, mechanic apron, face mask, and gloves should also be used to protect eyes, nose, mouth, and skin from splashes of gasoline, diesel, and other fluids that may be harmful to the different parts of your body.

- The needed replacement parts if there are any worn or damaged components that may need to be changed.

Safety Tips to Remember

Before going through the different procedures that we will be showing you here, it is important to consider the following safety tips to ensure your well-being while working on the vehicle:

- Always disconnect the negative terminal of your car's battery before starting to prevent any possible shocks and sparks that could result in a fire.

- Wear safety equipment to protect yourself from any splashes of fuel or other fluids that may be harmful to your skin, eyes, and breathing.

- Be sure to properly support the vehicle with jack stands during maintenance work.

- Ensure that all hose clamps and connectors are tight after completing the procedure.

- Keep away from things that generate too much heat or that could potentially cause sparks to avoid igniting the sensitive parts of the fuel line as well as its fluids.

- When finished, remember to reconnect the negative terminal of your car's battery.

Ways to Relieve Fuel Pressure Without Starting the Engine

There are several ways to relieve fuel pressure without starting the engine, and the following sections will outline each of them.

Method 1: Disconnecting Fuel Lines

The first method is to disconnect one or more fuel lines from the vehicle's system. This can be accomplished by locating the fuel line that runs from the pump to the injectors and then disconnecting it at either end. Once this is done, gas will slowly start to drain out of the line, relieving any built-up pressure in the system.

Make sure that you have a container, rag, or towel ready to catch any spilled fuel, and be sure to wear protective gear such as gloves and safety glasses. Additionally, it is important to note that this method is not recommended for vehicles that have an electric fuel pump, as it can cause damage to the pump and other parts of the engine.

Method 2: Manually Triggering Fuel Pump Relay

The second method is to manually trigger the fuel pump relay. This process involves locating the fuel pump relay in your vehicle's fuse box and triggering it by connecting a jumper wire from terminal 30 to 86.

Once connected, you should be able to hear the fuel pump running and see any pressure build-up on your pressure gauge. When you are sure that pressure has been relieved, disconnect the jumper wire and secure all connections before continuing with further diagnosis or maintenance.

Method 3: Draining Fuel Tank

The third method is to drain the fuel tank. This process requires you to locate your vehicle's fuel tank, which is usually located under the rear seat or in the trunk of your car.

Once located, you can use a siphon pump or other device to begin draining the fuel from the tank until its contents have been relieved. It should also be noted that this method should only be used if absolutely necessary, as it may not be safe depending on how much fuel remains in the tank and should therefore only be done with extreme caution.

Things that Can Go Wrong

There are several risks associated with these methods from a non-professional, DIY perspective. Without the proper expertise and tools, you may straight-up cause damage to the different parts of your vehicle such as the following:

- Damage to the fuel pump due to incorrect connections

- Leaking of fuel from disconnected lines which can create a fire hazard

- Immediate loss of power due to draining too much fuel from the tank

- Incorrect use of jumpers and other tools leading to short-circuiting or sparks

Additionally, improper ventilation when working with fuel can also lead to dangerous levels of fumes that could become combustible. It is therefore important not to overlook the risks when carrying out these tasks on your own.

Furthermore, it is critical to maintain the correct fuel pressure in an engine for optimal performance and efficiency. When fuel pressure is not calibrated correctly or in accordance with your vehicle manufacturer's specifications, it can cause a range of issues that may significantly damage the engine.

Poorly calibrated fuel pressure can lead to increased levels of soot production and degraded overall performance, resulting in poor acceleration and sluggishness. If left uncorrected, incorrect fuel pressure may also cause improper combustion timing which could lead to pre-ignition or detonation. This can create high cylinder pressures which will ultimately lead to blown head gaskets, cracked pistons, a faulty sensor, or damaged valves.

To prevent these costly components from being damaged due to incorrect fuel pressure, regular maintenance should be conducted by a certified mechanic who can adjust the fuel pressure accordingly. Proper maintenance not only ensures that engines operate correctly but also extends the life of an engine and its associated parts. Therefore, it is important to take proper care of an engine's fuel system to prevent costly repairs down the road.

Determining the Ideal Fuel Pressure for Your Engine

To determine the correct fuel pressure for your engine, you must consult your vehicle's owner's manual or refer to a certified mechanic. Additionally, it is important to note that if you are using an electric fuel pump, you must ensure that the voltage supplied to the pump is consistent with the manufacturer's specifications in order to prevent any damage from occurring.

Calibrating the fuel pressure should only be performed when absolutely necessary and one should take extra precautions to not cause any further damage to their engine or other components of their vehicle.

This can be done by referring back to manufacturer-approved methods as outlined in your auto's user manuals or seeking professional advice from a certified mechanic who can recommend the most effective way to reduce fuel pressure based on the make, model, and configuration of your ride.

Symptoms of Incorrect Fuel Pressure in an Engine

Incorrectly calibrated fuel pressure can cause a range of issues that can put a strain on an engine and its related components. Therefore, it is important to identify the signs of incorrect fuel pressure so that action can be taken to rectify this issue as soon as possible.

There are some common symptoms of incorrect fuel pressure, which you should pay attention to after manually relieving the fuel pressure of your engine. These include the following:

- Rough idle

- Engine misfires

- Decreased acceleration

- Loss in power or performance from the engine

- Overheating

If you notice any of these symptoms occurring in your vehicle, it would be wise to take it to a qualified mechanic, your car dealership, or an auto shop for further inspection and diagnosis. The technician should be able to determine whether or not the fuel system needs further attention or parts replacement.

Conclusion

Relieving fuel pressure without having to start your engine is a useful skill for any mechanic or DIYer. By following these steps, you will be able to quickly identify any issues with your vehicle's fuel system and take the necessary steps to remedy them.

However, it is important to remember that any changes made should be done with extreme caution and under the guidance of a qualified professional to ensure a safe and successful process of doing it.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment