Automobiles have increasingly become cozier and safer over the years. Automobile manufacturers have invested heavily in the suspension of vehicles. They have moved from the conventional steel springs and widely embraced the air suspension system.

Air suspension problems highlights

- Level of importance:medium

- Common reasons:internal suspension failure, electronic problem

- DIY inspection:impossible

- DIY repair:impossible

- Average price in shops:$550 - $1,900

- Average time:5 - 20 hours

- If ignored:fatal failure, car drops, hard driving

What is an air suspension compressor relay?

The compressor in the air suspension system of a car opens and closes after assessing the weight of the car. It will therefore adjust the amount of air pumped into the bellows. An air suspension compressor relay is a switch that imparts magnetism to complete the opening and closing of the compressor. It is generally remotely operated.

The air suspension compressor relay being electronically operated switch is the one that switches the compressor ON or OFF. The relay is wired to the pressure switch which manually closes off air or lets it in. Failure of any of these parts will make the whole air suspension system fail. Modern vehicles rely heavily on electronically controlled air suspensions system.

While the air compressor is tasked with the role of supplying the bellows or the suspension bags with pressurized air, it is the relay that ensures the vehicle moves in effortless motion. This relay is critical in the optimal operation of the air suspension system. Like any other car component, the relay can fail or malfunction. Let us take a look at the top causes of air suspension compressor relay failure.

Why does the air suspension compressor relay fail?

Like any other car component, the air suspension compressor relay can stop working as intended. Any malfunction of this air suspension system part means the comfort offered by your car will be greatly compromised. There are several reasons why this can happen and they include the following.

1. Poor electrical connection

The electrical wiring of the air suspension system can wear out or just get damaged leading to the relay malfunctioning. Being an electrical component, any connection issue will affect the relay's capability. Damaged harnesses and spoilt sensors will also lead to the relay malfunctioning.

2. A fault in the air suspension control system

If there is an airbag leakage, or there are issues arising from spring problems or driving on rough roads, then the relay may develop issues. These issues mean that the relay cannot effectively get the correct readings from the different air suspension components and hence is unable to output the correct data.

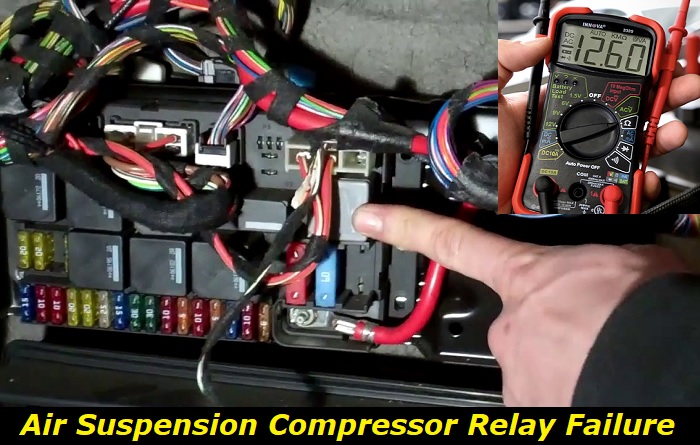

How to test the air suspension compressor relay

If you start experiencing a bumpy ride in a car that has always been smooth and comfortable, it is time you checked the air suspension system. The first place you might consider checking is the relay. The sooner you check what the issue is the better for you and your car since this helps prevent further damage to the car and it will save you money. Here is how you can check whether your car's air suspension relay is intact;

- Test for air leaks

This test involves using a bottle of water and soap. You will start by filling a bottle with water and then adding a few drops of soap solution into it. Shake the bottle to mix the soap with the water.

Identify the fitting areas of the air suspension system and pour the water solution on each as you observe. If there will be air hissing out of the fitting area or if there is a puncture on the system, you should observe bubbles once you pour the water.

Depending on the severity of the leakage, there are several solutions to air leaking from an air suspension system. Observe and confirm the type of damage you are dealing with. There are times you will only need to tighten the fitting and the system will be restored. There are other times you will be required to remove the cracked or damaged piece and replace it with a new one. Of course, you should perform the same water test after repairing a leak.

- Test the pressure switch

A faulty pressure switch will also make the air suspension compressor relay malfunction. A faulty pressure switch means the compressor will never get filled. This then means the vehicle will never sufficiently lift.

To conduct this test, you will need to jack the car into the air first. You will then drain the pressure tank all air with the drain plug found by the side of the tank. Switch the car to ON to test the pressure switch. The test will require placing a test light on either side of the wiring system. If the test light works fine, then it means the pressure switch has no problem.

Put in other words, you should place one lead of ohm meter to one of the loose wires coming from the pressure switch. Normally, the air pressure switch will close when subjected to pressurized airflow. In this test, the ohm meter should read zero ohms if the pressure switch has no issues.

If the test light doesn't light up, then it means the switch is faulty. There is nothing much you can do about a failed pressure switch other than to replace it.

- Test the compressor

The compressor is tested by checking its power. This can be done by simply testing whether the pressure is working. The test will best be done on a compressor that is not filled. The test will involve using a test light which will show whether the compressor is generating enough power to light it up.

If the test light gives light, then the compressor is working fine. On the other hand, if it doesn't light, then start by checking the air suspension compressor relay running power towards the compressor or to the fuse of the compressor. Doing this will help you know whether a faulty fuse is the cause of the system not working. A faulty fuse should be replaced and the conducting the test again to confirm the system is fine.

Testing the compressor requires setting your DMM to the direct current (DC) volts. You should then disconnect the electrical connector from the compressor. Then turn on the engine and observe whether the compressor runs.

Can one drive a vehicle with a faulty relay?

A faulty air suspension system in a vehicle means that the vehicle will not respond well to its weight and load. It will sag and make noise when you drive the car. While it is possible to reach your destination in such a car, the journey will be quite uncomfortable. To add to this, if you are driving off-road, the ride will be very bumpy and noisy.

Driving a vehicle that has a faulty air suspension issue can cause further damage to the other parts and systems of the car. Don't forget that such a car is difficult to control in case of an emergency. Rather than risk, do a few tests to establish where the issue is. The problem might be as simple as a loosened fitting.

How can I avoid having a faulty air suspension compressor relay?

Every vehicle component ages and reaches the end of life. The wearing out can be fast especially if you neglect to service and regularly check your vehicle. In the case of the air suspension system, you should heed small warning signs such as when you experience a rough drive more than you are used to. Regularly check the dashboard to confirm there are error messages displayed.

During scheduled service, tell your mechanic to check whether the air suspension components are in order. In many instances, the mechanic will do engine service and assume everything is in order. Once in a while, take a look at the system or have the mechanic check. This way, you are far more likely to catch a problem in its infancy.

How much will it cost to fix a faulty air suspension compressor relay?

As discussed above, establishing whether the air suspension compressor relay is the problem requires performing a number of tests. If you finally establish that it is indeed the relay that has an issue, you must replace such a relay immediately.

The testing of the various components of the air suspension system is pretty easy and can be done at home. If you don't have the expertise to fix a faulty relay, visit your nearest dealership and have the work done fast. The average cost of fixing a faulty relay ranges between $1,200 and $2,000 depending on the make and model of your car.

Conclusion

The air suspension compressor relay plays a very important role in keeping the car fully functional. An issue affecting any part of the air suspension system means that the relay will malfunction and make the whole system misbehave.

We have seen that conducting the above tests is easy and can be done at home. You can have an extra relay if fear the one in place or the system might fail. But the most important thing though is to ensure regular service is done on the vehicle to avoid air suspension system problems.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment