Spark plug holes keep the spark plugs intact during firing. When starting your engine, the spark plugs will initiate ignition to proceed with fuel combustion inside and generate power. However, if these holes have been stripped and caused loose threads, your spark plugs will not touch the candle that produces the spark. Your car will have trouble starting.

Engine repair mistakes highlights

- Level of importance:extremely important

- When done:DIY repairs or diagnostics

- Cost of mistake:$250 - $4,000

- How to avoid:professional inspections, getting help from mechanics

- Consequences:broken engine, need for engine replacement

- DIY solutions:not many

Why Do Spark Plug Holes Wear Out?

Stripping happens when you have detached insulation in your spark plug wire. Your spark plug holes may go brittle when attached to the cylinder for long without being removed or replaced.

Another reason for stripped spark plug hole threads is overtightening them when attaching to the cylinder. The excess force causes them to break apart and go through in-between spark plug threads. Or the event can also strip the spark plug threads themselves.

What Happens if your Engine Has Stripped Spark Plug Holes?

Having stripped spark plug holes can cause irregularities that may lead to failure of combustion.

- Misfire

Misfire happens when your engine momentarily loses power or rpm, then regains them. It occurs when you try to idle but results in rough or uneven idling. It misfires when one of the cylinders has stripped spark plug holes.

- Trouble starting

Because one of the cylinders cannot hold the spark plug enough to create an ignition, you may have a problem starting.

- Engine failure

Excessive wear from worn-out spark plug holes could lead to engine failures due to irregular operation. Having one cylinder fail to keep spark plugs intact could lead to catastrophic and costly damages.

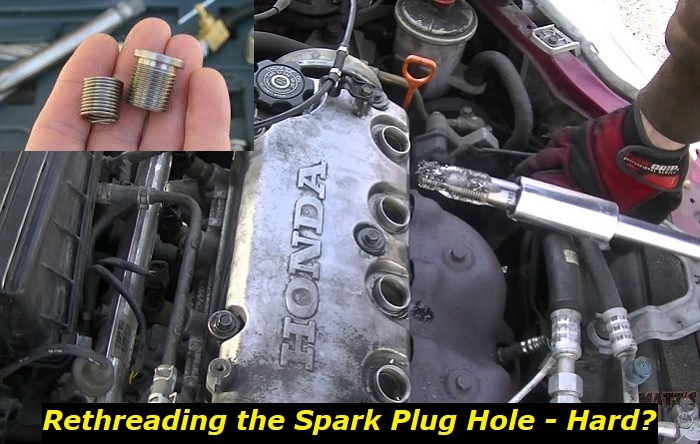

Rethreading tools for Spark Plug holes

Spark plug holes seem like irreversible damage. Rethreading will bore a larger hole and will not match the spark plugs. The challenge is how the spark plugs will fit into the newly threaded hole. A lot of DIYers turn to inserts. These inserts have wire coils torqued into the spark plug hole to create internal screw threads to fasten spark plugs.

Another challenge when rethreading is preventing the chipped metal shavings from getting into the engine. Forgetting to apply lubrication at this stage could lead to serious engine damage.

There are different rethreading tools to rethread or restore your stripped spark plug hole. But before you start threading, we have a few notes when removing the spark plugs to prevent more damage in the threads.

Removing the spark plug

It is essential to check any resistance from the spark plug before trying to remove it with full force. If you have not changed your spark plug for ages, use a PB blaster to spray it down the threads that fasten them together. A WD-40 is a good substitute. Do not remove it forcefully. Turn it clockwise and counterclockwise until you feel it has loosened enough.

Method 1: Restore, repair, or chase the threads

Chasing the threads is not a complete rethreading process, as you will clean them in this process. These tools are better used when the spark plug holes have only a small damage on the threads.

If the threads in the hole are still intact, you can use a thread chaser. A thread chaser is a specialized tool used for repair and maintenance. It looks like a double-ended tap with external threads of two different sizes. Although its purpose is not to create threads, it will help clean, reform, restore, or chase existing threads. If they have been totally stripped out, this tool is useless.

Unlike taps and dies, this tool is M42 top-speed or M2 steel. You usually use it to clean the threads of spark plug holes every time you replace the spark plugs.

It is an amazing maintenance tool to prevent your spark plug holes from getting damaged during spark plug replacement.

You only need to apply some grease on the threads of the tap to catch some metal shavings that may chip out during the process. Thread chasers only have taps of the usual size for spark plug holes 14 mm and 18mm. Choose the right size.

Use a regular socket and a hand ratchet to hold the greased thread-chasing tap from the hex. Insert the tap straight on the spark plug hole. You should not feel any resistance from the threads to preserve existing good ones on the hole. And turn the socket clockwise by hand.

Turn it as far as the tap can go. Use your hand to keep tapping until you cannot turn the thread chaser. Remove it by turning the tap the other way with your hand ratchet.

A back tap tool is another specialized tool or spark plug hole. It is a collapsible type of tap that expands when inserted into the spark plug hole and runs backward as you take it out from the hole. It provides straight threads when there are only the first few threads damaged in the spark plug hole.

When using the back tap tool, grease it to catch metal shavings. Stick it inside the spark plug holes as much as you can. Turn and tap it with the tightening nuts found at the top. Turn it until it goes further. Then use a wrench to turn the back tap and remove the entire tool from the hole.

Method 2: Use inserts with Rethreading Kits

Rethreading kits are a popular set of tools to rethread spark plug holes.

When the damage is large enough that you cannot restore it by reforming or chasing the threads, owners use inserts on newly-threaded holes to accommodate the spark plug.

A Time Sert uses a solid bushing insert with thin walls made of stainless, carbon steel, or sometimes-copper. It produces a more permanent and reliable repair than wire-coiled inserts, slowing fully-applied torque on spark plug holes. The kit includes a drill bit, a counterboring tool, a step tap, an inserting bit, and different-sized inserts.

When using a Time Sert kit, tap a few threads first. The step tap has the same pitch and size as the spark plug holes. Slowly tapping it will enlarge the diameter following the size of the insert. You don't have to drill the hole with this tool.

Place the insert by lubricating it first with grease or oil. Screw the bushing insert into the hole by hand. The insert would thread quickly because of its self-threading design. With a tap handle, turn the inserting tool until the insert has seated smoothly. Turn the tap handle in reverse to remove the inserting tool.

The good thing about this kit is it makes straight threads that coincide with the original threads of the spark plug hole. And this repair method is permanent compared to Heli coil.

Heli-coil is a spring-like wire coiled insert used to repair and tap insert screw threads on a spark plug hole.

The kit includes a drill, a tap, an installation bit, and inserts.

A Heli coil is a popular thread-repairing system. However, it got some flaws. It does not seat straight as precisely as a bushing insert on the original thread. Plus, it has tendencies to fly off when you have to replace your spark plugs.

- Use the tap that comes with the kit and attach a handle to it.

- Apply some grease to catch metal shavings and start tapping threads. Tap until you feel some resistance.

- Use a ratcheting wrench until the tap goes to the bottom of the hole. Turn the ratchet counterclockwise until you unscrew the tapping tool.

- Inspect and clean metal shavings.

- Select a Heli coil that fits into the spark plug. Apply RTV sealant to the Heli coil external threads. Place the Heli coil with the attached spark plug into the hole using a spark plug socket. This will spread out the torque until the top of the Heli coil seats on the cylinder head.

- Unscrew the spark plug. The Heli coil must be flushed with the spark plug, and it should not unscrew with the spark plug.

- Inspect the surface and clean off the residue from RTV.

- Install the spark plugs back.

The Dos and Don'ts of Rethreading Spark Plug Holes

Many owners who turn to DIYing their stripped threads fail with a few procedures when rethreading.

- Always make sure to work on the spark plug hole with closed valves. This measure prevents metal shavings from going into the engine.

- Avoid using anti-seize products on your spark plug as it affects its torque specs.

- Listen to your technician, not the shop owner recommending replacing the cylinder head.

- Don't use a thread chaser if the spark plug has blown out.

- Prepare these tools before starting: air compressor, hand ratchet, air tools, greaser, and socket sets.

Our Best Recommendation

If your spark plug holes have only a few threads damaged and are still intact, do not start drilling. You can chase the threads to restore them.

However, when worsts comes to worst, and you are avoiding the high costs of repairing spark plug holes- which may go up to $1000- the best insert to use is a bushing insert. It is more durable and sits tight on the tapped threads of the spark plug holes.

In most cases where you have done rethreading correctly, the insert replacements could last the vehicle's lifetime.

However, if you are not comfortable with metal shavings risking the efficiency of your engine and budget is not an issue, the best way you can repair the hole is to bring it to your trusted service shop for rethreading. They have all the tools needed and the correct repair procedures for your stripped threads on the spark plug hole.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment