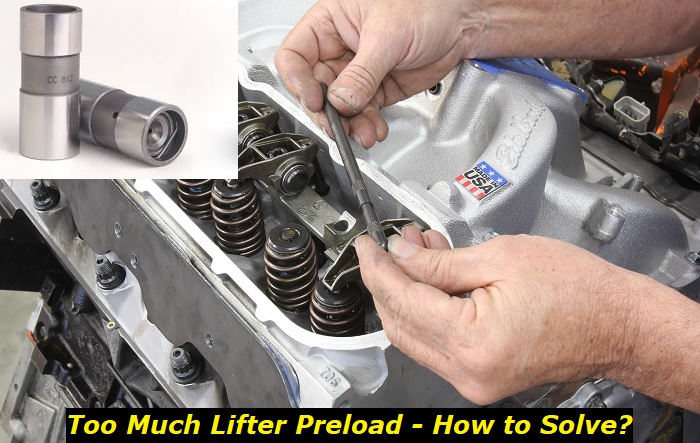

Too much lifter preload can be a serious problem for any engine, and it can cause a variety of issues that range from decreased performance to catastrophic failure. If you're experiencing problems with your engine or suspect that too much lifter preload could be the culprit, then this is the article for you.

Lifter problems highlights

- Level of importance:Medium

- Commonreasons:Age, poor oil, too high oil viscosity, mileage

- DIY inspection:Almost impossible

- DIY repair:Possible but very complicated

- Price for repair:$450 - $1,200

- Can you drive?Usually, yes

- Ways to fix:In most cases, replacing the lifters will be the only proper choice

What Does the Lifter Do in an Engine?

The lifter is a part of the engine that helps it work. In its general design, it connects the push rod to the camshaft and helps control how much fuel and air go into the engine. In doing so, it must follow the recommended preload by the engine manufacturer.

Too much tension between the lifter and push rod can cause problems like excessive wear on parts of the engine, high heat levels, or an engine that doesn't run efficiently.

What are the Main Types of Lifters?

There are basically two main types of lifters. One is the mechanical lifter and the other is the hydraulic lifter. Here is a quick look at what each does:

- Mechanical Lifters

Mechanical lifters use a system of springs, arms, and levers to convert the force from the camshaft's rotation into vertical motion. The mechanical action of the lifter helps it supply the correct amount of fuel and air to each combustion chamber as the engine revs up and down.

- Hydraulic Lifters

Hydraulic lifters work differently than mechanical ones. Instead of using a system of arms and levers, hydraulic lifters mainly utilize pressurized oil to move the pistons up and down when they are activated by the camshaft. This ensures that there is an even distribution of power throughout the cylinders, resulting in efficient engine performance with minimal wear on components.

Both types of lifters have their unique advantages and disadvantages, so the choice of which one to use will depend on your engine type. Ultimately, both are important components in ensuring that your engine runs smoothly and efficiently.

What is Lifter Preload?

Lifter preload is the amount of tension between the lifter and its associated push rod. To get the ideal lifter preload in a vehicle, you need to measure the tension between the lifter and its related push rod or the oil pressure depending on the kind of lifter that your engine has as well as the type of engine that you have.

Then, compare it with the manufacturer's recommendations, which you can see in the service manual that comes with your vehicle or that can be downloaded online from the official webpage of your automaker. Having precision in the way that your lifted preload is configured helps your engine work better and has less wear on its parts.

What Happens When There's Too Much Lifter Preload?

When there is too much lifter preload, it causes greater friction within the engine system by forcing metal parts against each other with greater force than necessary. This increases heat levels within the engine, which can result in accelerated wear and tear or even severe damage if not addressed quickly.

Excessively high temperatures from preload can also lead to engine knocking, which is caused by a loss of compression in the cylinders.

Key Symptoms of Too Much Lifter Preload in an Engine

The effects of too much lifter preload can affect a vehicle in various ways. There are also variations in the way that they manifest in hydraulic lifters and mechanical lifters. Here is a list of key symptoms to look out for:

- Mechanical Lifters

Excessive tension between the lifter and push rod can cause accelerated wear on the camshaft lobes, valve springs, and other components. This may lead to noisy operation or engine knocking due to loss of compression in the cylinders.

- Hydraulic lifters

Too much preload can result in oil pressure drop as well as cylinder head distortion due to increased heat levels within the engine. This can cause a decrease in power output and acceleration. Additionally, hydraulic lifters may produce a "ticking" sound if too much preload is present.

Since both lifters are built for the same purpose of ensuring proper engine operation - albeit possessing different builds and with varying advantages - their failure could generally mean reduced performance and noisy operation of the power unit. If ignored, it can lead to overheating or breakdown of the engine.

Solutions to Fix an Engine with Too Much Lifter Preload

Should you notice signs of too much lifter preload in your mechanical lifter or hydraulic lifter, bring your auto to a qualified mechanic without further delay. Normally, the solutions for this include the following:

- For Mechanical Lifters

The mechanic will usually adjust the rocker arms carefully to reduce tension and set the correct preload for the lifters depending on the size, type, and recommendation of your engine manufacturer. If any of the components are worn or damaged, the lifter assembly and other conjoined components may need to be replaced altogether.

- For Hydraulic Lifters

In cases of hydraulic lifter preload, oil pressure needs to be adjusted with a gauge. Meanwhile, the parts that show signs of wear or damage should be replaced. Again, this may involve the whole lifter assembly plus other affected parts.

In general, the replacement of key parts may be needed if symptoms persist over time and are not addressed immediately. It is also prudent to replace worn-out components as soon as possible, particularly in the case of hydraulic lifters where wear and tear are more likely.

Normally, the key parts that may tend to go out first are the camshaft and valve springs, which are critical components in the operation of the engine. If the problems spread out due to negligence or other factors, the other parts that may need to be changed are the crankshaft, rocker arms, push rods, and lifters, as well as gaskets.

The failure to address an issue with too much preload can lead to a decrease in fuel efficiency and an increased risk of breakdowns due to excessive wear on parts. Therefore, it is important to take steps toward fixing this problem immediately if symptoms are detected. The worst-case scenario is a compromised engine that may need a replacement, and that will certainly burn a hole in your budget.

It is advised to contact a mechanic or automotive specialist if you experience any issues with engine preload or performance, as this will help to keep your vehicle in optimal condition and prevent excessive wear and tear on components.

Different solutions will have their own advantages and disadvantages, so the choice of which one to use will depend on your individual needs. It is important to address any issues you might find as soon as possible to minimize the risk of more expensive repairs being needed later on.

If you feel the need to replace any key components, it is important to use only high-quality parts from reliable manufacturers to guarantee smooth performance.

How Can One Prevent Excessive Lifter Preload?

As they say, "prevention is better than cure". So, to avoid this particular hassle that will certainly put a dent in your budget, it is important to follow the regular maintenance schedule of your auto.

Among the things that will be checked is the engine of the vehicle. To prevent excessive lifter preload, the correct amount of tension should be applied to each push rod and lifter pair in accordance to your engine manufacturer's specifications.

This can be done by gradually adjusting the rocker arms until they are secured at the right level of tension. In the case of hydraulic lifters, the pressure should be adjusted via a gauge within the ideal level. If the condition persists, it may be necessary to replace worn or damaged components as discussed earlier in order to restore proper tension levels in the lifter.

With regular maintenance and careful attention paid to lifter preload, an engine will function efficiently with minimal risk of damage due to wear or heat-related issues.

Conclusion

By taking steps to prevent or fix an engine with too much lifter preload immediately after noticing the symptoms, you can save yourself the headache and expense of dealing with major problems along the way.

Regular maintenance checks should help identify any potential issues before they become serious enough to warrant heavy repair or replacement costs. If ignored, these issues can quickly lead to more costly repairs, breakdowns, and even engine failure. With regular maintenance and attention to detail, you can ensure optimal performance and longevity of your vehicle.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment