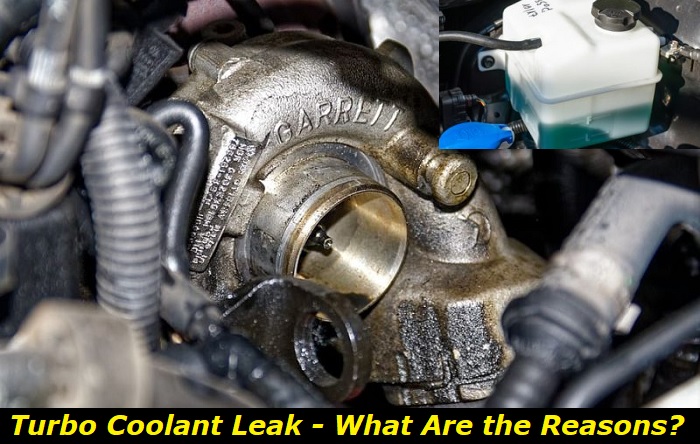

Turbo coolant leaks can be a major nuisance to deal with, as they can lead to serious damage down the road. When there's a leak in this system, it may result in the engine overheating, which can lead to accelerated wear and tear. In extreme cases, a turbo leak could even cause an engine fire if left untreated for too long.

Coolant leaks highlights

- Level of urgency:very high

- Commonreasons:cooling equipment failure, pipe connections, radiator damage

- DIY diagnostics:possible but complicated

- DIY repair:mostly impossible

- Price of repair:$350 - $1,500

- Time for repair:3 - 8 hours

- If ignored:overheating, equipment failure

If you suspect that your vehicle is having this problem, here are the most likely causes of the issue:

1. Leaks from Turbo Coolant Lines

Turbochargers come in different designs depending on their vehicle application. Although most turbochargers run on oil for cooling, some utilize engine coolant for a more efficient way of cooling. The turbo coolant line, then, is an important part of a vehicle's turbocharger system and needs to be assessed for possible leaks in this instance.

The visual cues for a potential leak in the turbo coolant line are quite straightforward. If there is evidence of coolant leaking from the hose or pipe, it may indicate a problem with the connection itself or another part of the system. In some cases, fluid residues near where the hose connects to the block may also denote a leak. Other symptoms to look out for include white smoke from engine exhaust, increased engine temperature than usual, and air bubbles in the cooling system hoses when bleeding.

Various tools can also help pinpoint suspected areas for leaks. A pressure test gauge can be used to check for pressure drops in the turbo coolant line and other parts of the system. A digital thermometer can also be used to measure temperatures near where the hose connects to the engine block, which will help identify a faulty connection or gasket.

One of the most common problems that cause leaks in the turbo coolant line is an ill-fitted gasket or defective seals. This could occur as a result of improper installation, over-torqued components, and regular wear and tear due to aging. In such cases, replacing these parts with new ones should address the problem.

Other potential causes include incorrect routing of hoses around exhaust manifolds, broken couplings, deteriorated hoses, cracked vacuum lines, and damaged O-rings. If there are issues with the turbocharger itself, then it may be necessary to replace it entirely.

To prevent issues with the turbo coolant line, it is important to make sure that all connections and components in the system are properly tightened and fitted. It is also important to ensure that hoses and lines are routed correctly around exhaust manifolds as incorrect routing can cause heat damage, leading to leaks in the future. Regular maintenance of other parts is also essential for keeping the turbo coolant line running efficiently. This includes replacing vacuum lines when they become brittle or cracked, cleaning oil drains regularly, and inspecting sealants for any further deterioration.

2. Worn Turbo Oil Seal

Most vehicles rely on turbocharger oil for both the lubrication of their parts and cooling. This is to streamline their design and for efficiency's sake. Now, this definitely begs the question as to where the engine coolant may be coming from. In this scenario, we're positive that the coolant's origin is not in the turbocharger itself. Instead, it may have just seeped through the worn oil seal of the turbo.

You may apply the same techniques mentioned in the first part of this list to confirm whether or not there is a leak in your turbo that may be causing its oil to mix with your engine coolant. You can also detect this by checking the seals if they are indeed showing signs of major wear.

Likewise, include in your assessment the gasket, O-rings, and lines that may be serving as possible entry points of the coolant contaminating your turbo. Replace any of these parts if you find one of them to be the culprit for all this issue.

As mentioned, the coolant may be coming from somewhere else, so you are not yet done with the repairs at this point. Therefore, it might be prudent to check the possible sources of the coolant getting into your turbo which can be one or more of the factors presented in the next few items of this list.

3. Central Housing Rotating Assembly Internal Crack

When assessing internal cracks in the central housing rotating assembly of the turbo, there are various visual cues, symptoms, and tools that can be used. These include inspecting the external surfaces of the components for wear or damage, listening to identify any unusual noises which may indicate a problem with the turbo's rotation, and using a borescope or ultrasound device to view inside.

If a crack is found within the assembly, this can often be attributed to fatigue caused by temperature variations or vibration from an imbalance in the system. Commonly affected parts include mounting rings, threads, and seals. All of these should be inspected regularly as part of regular maintenance procedures.

In addition to fatigue-related issues, some other potential causes of cracks in this area include faulty installation, contamination or corrosion resulting from poor fuel quality, and the use of incompatible parts. In most cases, the only solution is to replace the affected parts. Depending on the extent of damage, this may involve replacing one or more components such as bearings, shafts, and seals.

4. Water Pump Failure

Coolant leakage itself is one of the main indicators of water pump failure. It is usually coupled with a decrease in engine performance due to overheating or inconsistent temperatures throughout the system.

In addition, groaning and whining noises coming from the area near the water pump are often strong indications that something has gone wrong. Visual inspection of hoses, clamps, gaskets, and other connections should also be done. If coolant is leaking from any connection or elsewhere around the pump itself, it can indicate a breach or crack in its housing.

In terms of common causes behind such issues with water pumps, there are a few that tend to be more frequent than others. A worn-out impeller, which is the part of the pump responsible for pushing coolant through, can cause coolant loss in certain cases.

Additionally, a lack of lubrication or the use of subpar parts during initial construction can lead to further problems down the line. The good news is that these causes are generally easy to fix with the help of a mechanic and involve replacing the water pump or its individual components with new ones.

5. Blown Head Gasket

When assessing a blown head gasket that is leaking coolant into the turbo, it is important to first identify any visual cues of the problem. This can include coolant leaks or oil residue in and around the turbo area, as well as smoke coming from the exhaust pipe. It may also be possible to smell antifreeze or gasoline fumes in the engine compartment.

Additionally, listening for signs such as bubbling noises within the radiator cap when running hot could indicate a blown head gasket. If these visual cues are present, it's necessary to use a scan tool and pressure gauge both before and after an engine run to confirm whether there is excessive internal pressure or vacuum due to the leakage.

The common causes of this issue can include a faulty gasket, head bolts that are not properly tightened, or a warped cylinder head. These problems can be rectified by replacing the parts with new ones and ensuring that they are correctly fitted and tightened. Other common parts which may need to be replaced include the turbo inlet pipes, oil cooler, exhaust manifold gasket, and intercooler piping.

It is important to ensure that the said components fit properly and do not have any gaps or leaks. Additionally, if the head has been machined or resurfaced it's essential to check for cracks around the combustion chamber before reassembly.

Lastly, when installing any of these new components it's important to follow the specified torque settings listed in the manufacturer's manual. This will help ensure the head gasket is correctly fitted and that there are no leaks. In some cases, it may be necessary to use an additional sealant or a high-temperature gasket maker when reinstalling parts before reassembling the turbo.

6. Other Sources

There are many other parts in your engine bay that may be causing coolant to get in your turbocharger. Among the other likely culprits are those components nearby, including but not limited to ruptured coolant lines near the turbo, a punctured radiator, a loose radiator cap, a damaged thermostat housing, and other parts where coolant typically circulates.

Should you detect the issue in any of them, have the problematic component repaired or replaced immediately.

Conclusion

As shown here, many things can go wrong that can lead to coolant leaking out or seeping through your turbocharger. If the turbo itself uses engine coolant for maintaining its ideal operating temperature, you may want to check its housing and lines for possible sources of leaks.

However, if it mainly uses turbo oil for cooling, then the engine coolant may be coming somewhere else. In such a scenario, better look for nearby engine components where coolant normally circulates as the possible causes of the contamination in the turbo.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment