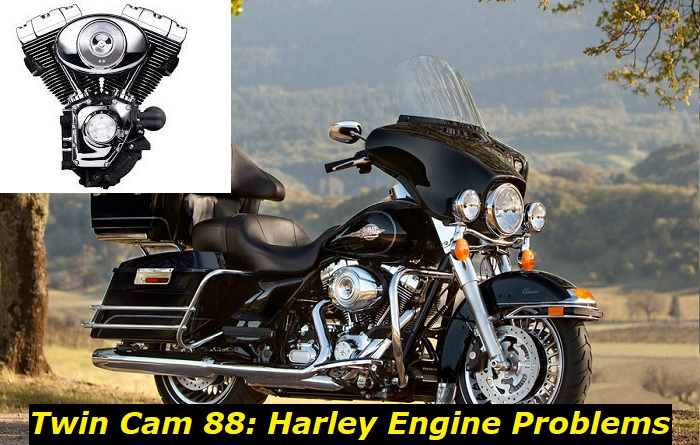

The Twin Cam 88 from Harley-Davidson is not entirely bad. However, this engine model has gained notoriety over the years due to the issues associated with it through either word of mouth or negative writeups.

In this article, we will shed light on the most common problems encountered by bikes with this unit to help you better understand the potential risks of its ownership. Likewise, this will present you with some crucial nuggets of information that will help you determine the right solutions for the possible issues that you may come across with the engine.

Cam Chain Tensioner Design Flaw

If you go on asking people who are familiar with the Twin Cam 88, one of the first things that they will likely tell you about it is the cam chain tensioner issue that has haunted riders over the years. According to veteran mechanics, the problem can be traced back to the design flaw in the engine itself.

This main weak point of the Twin Cam 88 can happen as early as 15,000 miles on the bike's clock. It was blamed on the spring-loaded cam tensioner which delivered too much strain on the tensioner shoes.

The kind of material utilized for the shoes itself was also a key contributory factor to the issue. Originally, the plastic used in the shoes was intended to last at least 30,000 mileage. However, that was not the case here as complaints of cam chain tensioner problems piled up on the Twin Cam 88 bikes.

Based on accounts of owners and mechanics, the chainsaw-like pressure of the tensioner combined with the use of plastic in the tensioner shoes provided a perfect recipe for the quick wear of the Twin Cam 88. The rapid wear of the shoes has a high probability to cause plastic debris to accumulate in the oil pathways of the engine along the way.

Over time, the accrued plastic shavings have a high likelihood to reach an alarming level wherein the collected contaminants will eventually result in serious lubrication problems for the power unit of the motorcycle. Without proper lubrication, the risk of failure for the engine becomes more and more apparent as time goes on.

In 2007, Harley finally rolled out an update that introduced a hydraulic tensioner to its new bikes. It came a bit late for the Twin Cam 88 though so the model never benefitted from such an upgrade.

There are plenty of ways to go around this particular mechanical flaw of the Twin Cam 88 though. Your first option is to convert your stock cam chain assembly to the mentioned hydraulic tensioner introduced by Harley in 2007. Another alternative is either buy compatible aftermarket replacements for your problematic cam chain tensioner and tensioner shoes or have your entire cam chain assembly changed completely using aftermarket parts.

Either way, we strongly recommend consulting your mechanic first for advice before proceeding with any upgrades or replacements for your bike. Likewise, have them perform the job for you to ensure that everything checks out well in the end.

Only a few would tell you that they have never encountered this issue with their Twin Cam 88 engine. Some have even claimed that they were able to ride their bike north of 50,000 miles without ever facing the cam chain tensioner problem. Either they are very lucky or they have provided an extraordinary amount of care with their bikes. Another possibility is that they might have brought their bikes secondhand, and the previous owner may have already addressed the factors affecting the problem prior.

If you are yet to purchase a Twin Cam 88, don't forget to ask for its service history from the previous owner so you can determine whether or not the cam chain assembly has already been updated to save you from all the trouble mentioned here. Likewise, you may hire an experienced mechanic to help you check the merchandise thoroughly before buying it so you can get a better picture of what to expect.

Worn Compensator

The compensator is a device located in front of the Twin Cam 88 engine. Its purpose is to keep the engine running smoothly by compensating for changes in temperature and altitude. However, over time, the compensator can become clogged with dirt and debris, which can cause it to malfunction.

The symptoms of a malfunctioning compensator include rough idles, engine vibrations, and poor engine performance. The cause of the compensator problem is typically dirt and debris build-up or wear in the compensator itself.

It is worth noting that this problem also existed way back during the production years of the Twin Cam 88, and even the Twin Cam 96 suffered from this. It may not be as common as the notorious cam chain tensioner issue of the former but this issue seems to show up every now and then in reviews, reports, and forums dedicated to Harley bikes.

To fix the problem, the compensator needs to be cleaned or replaced depending on the nature of the issue. If you are convinced that your compensator is still working well, and it's just dirt causing all the hiccups in that part, a simple cleaning will let you take care of the issue.

To clean the compensator, you must first detach it from your bike. Cleaning it can be done in different ways. The simplest is through the use of a regular brush. However, the more effective solutions include utilizing compressed air to blow out the dirt and debris or soaking the component in a cleaning solution.

If the compensator is damaged or defective, it will need to be replaced. Thankfully, replacement parts are readily available and relatively easy to install.

As an alternative, you can upgrade it by converting it with the Screamin' Eagle compensator. A number of owners have also resorted to deleting the compensator but we strongly advise against this with the mere fact that the component has been placed in the system of your motorcycle for a good reason.

Cooling System Failure

The Twin Cam 88 is a great engine, but it does have a weakness when it comes to heat management. If not properly maintained, the cooling system can develop issues that can cause engine damage.

When having issues with your cooling system, don't hesitate to take it to a professional for repairs. A qualified mechanic will be able to diagnose and fix the problem quickly and efficiently.

If you are considering an aftermarket upgrade to provide better cooling for your engine, one way to go is by installing a fan on its side. This is not as intrusive as other options and it will definitely help a lot in pushing more air into your motor.

Carbon Deposits

One of the most common issues faced by owners of Twin Cam 88 engines is carbon build-up. Unlike some of the problems here which can be attributed to poor design choices on the part of Harley, this is fairly common in just about any other vehicle due to age. This can lead to a variety of symptoms, including loss of power, decreased fuel economy, and engine running rough.

One way to diagnose the possibility of a carbon build-up in your engine is to conduct a compression test. If the results of the test show that the compression in one or more cylinders is lower than normal, it could be an indication of carbon build-up. Another is to perform a leak-down test to identify any leaks in the engine.

There are a few ways for your mechanic to solve the problem of carbon build-up. One is through the use of a product that will clean the intake and exhaust valves. Another solution is via the installation of new valve seals if they are beyond saving.

Conclusion

One of the most important things you can do to keep your Twin Cam 88 in good running condition is to regularly inspect it for any signs of wear or damage. Pay special attention to the parts that are prone to fail in your ride, and if you notice any problems with them as well as any other parts for that matter, it's important to have them fixed by a mechanic as soon as possible.

Acting on time will prevent them from escalating into more serious issues and save you from more expensive repairs later on. Furthermore, keeping your engine in its top form is essential in ensuring your safety down the road.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment