Technologies ceased to stand still for a long time. Annually in the world of cars new decisions are applied in the field of suspension that does cars more comfortable and pleasant for operation. Among solutions of suspensions for passenger cars there are dependent and independent groups of technologies.

In the modern world independent multi-link suspensions became an exclusive prerogative of driving wheels of the car. Their use allows cleaning a problem of instability of a car at sharp dispersal or braking. On the second couple of wheels producers establish both dependent and independent options of suspensions. It is worth understanding what the main differences between various types of mechanisms are.

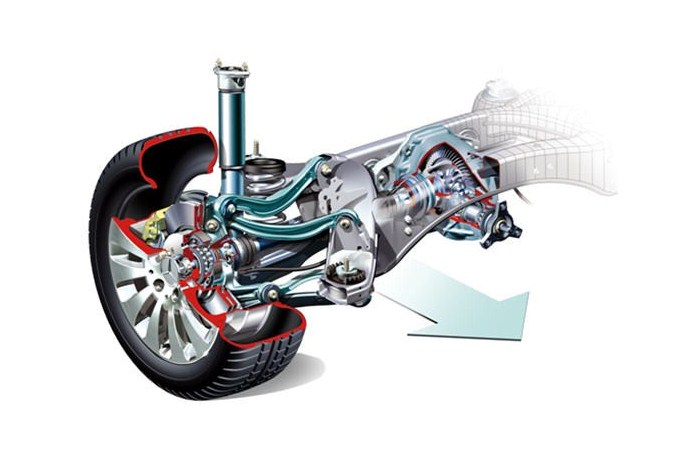

Double fishbone and multi-link suspensions

The constructions consisting of two or more arms became the most technological and safe types of suspensions in the modern automotive industry. Such construction provides the maximum stability of the car. The technology allows to achieve good stability in case of side sway, and also absence of unpleasant nosedive in case of hard braking.

Double fishbone suspension is simpler and cheaper in production, than multi-link one. Therefore many manufacturers of SUVs took as a basis construction with two arms. Its advantages can be describedby the following list:

- small number of prefabricated elements and high reliability of design;

- the technology allows to give maximum ruggedness to a car body at movement;

- the suspension fulfills the majority of roughnesses of the road, doesn't transmit them to interior;

- informational content of such technology is also noted by fine indicators.

Multi-link suspensions are more technological, they are often used in sports. The maximum stiffnesscan be softened withsprings which adopt all shock of the bad road on itself.

Multi-link suspensions with some additions to standard construction are used today in the majority of expensive cars. They give the maximum comfort, but are also very expensive construction. The high price here is not only in production, but also in maintenance and repair.

Suspension McPherson - optimum development

The creation of this suspension was back in 1960, but the technology received the real popularity only in the last decade. The quality of construction of a suspension is far from an ideal. Multi-link options are much more technological and reliable.

The main advantages of a suspensionMcPherson, named after its creator, are cheap and simplicity at production.

Many manufacturers write in technical characteristics of the cars information that model has multi-link suspension McPherson. In fact, it is nonsense, after all this suspension differs the following :

- presence of one arm;

- long plug with a spring;

- rather simple construction of stabilizing of the car in movement;

- change of an angle of installation of a wheel at different speed.

This technology isn't ideal, that's why the modern manufacturers try to upgrade it, by installing additional arms and making many other improvements. Thanks to such operation with McPherson suspension, today this option is one of the most used in automotive industry. The suspension is put often on leading pair of wheels.

The main disadvantages of suspension McPherson is insufficient reliability. Accessories of the lower part of such construction assume influence of all burrs of the road which lead to frequent repair of components. Nevertheless, due to its availability, McPherson became one of the most common types of suspension today.

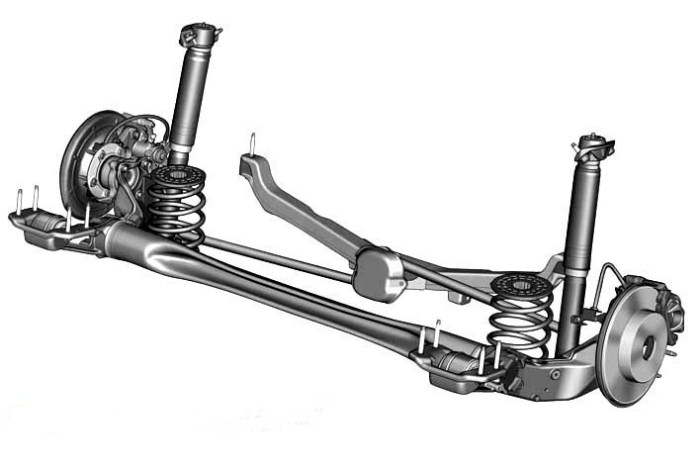

Axle suspension and technology De Dion

Axle suspensions are often set on rear wheels to avoid an uncomfortable trip. For this reason in some modern cars it is possible to go with comfort only in front seats. The simplest example of axle suspension- fixing of the back axle on helical springs and four arms. Such construction was used in all cars till 2008 of release.

Axle suspension became an obsolete method of the organization of system of a suspension for a long time. It is the cheapest way of building of such car's component, but it has specific disadvantages:

- too explicit transfer to salon of all information on the road;

- lack of elasticity in a suspension;

- possibility of a trip only on the good road, absence of posting of wheels;

- possibility of expensive damages of a rear beam.

One of the options of axle suspension is the type of construction De Dion. It is a lightweight option of the back axle from which practically all systems are removed. Most of modules in this option fastens on a car body, facilitating the axle and giving the car more comfort and ease.

But De Dion's construction doesn't solve the main problems of axle suspension. Therefore such options are used in the budgetary cars today. Manufacturers offer many options of improving axle suspension, but the best way is to replace it on multi-link.

It is possible to apply other option of suspension to not drive back axle – semi-independent construction. In this case the suspension is incredibly simple, it consists of two arms and connecting thin beam. Itis often used in small cars of the budgetary class.

Summing up

There are many new products today among suspensions for car. But all of them are based on three old and known types: axle, independent and semi-independent. These options are played up by manufacturers in the most different variations and connections to offer the buyer a unique product.

We shouldn’t forget that the comfort of a trip on the car depends not only on suspensions, but also on the quality of other accessories. It’s interesting, what suspensions prefer experienced driver, who reads our blog?

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment