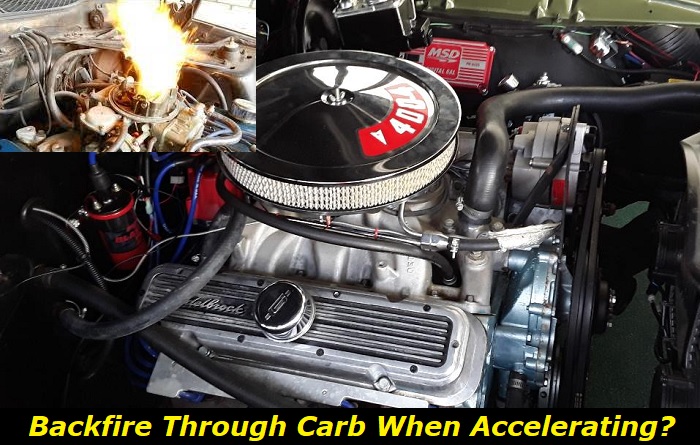

Backfire in the carburetor is a condition that occurs when the air-fuel mixture in the engine combusts outside of the engine. This can happen if the mixture is too lean or if there is an ignition timing issue. Backfire can damage the engine and cause it to lose power. It can also be dangerous if it happens while the vehicle is being driven.

Fuel supply problems highlights

- Level of importance:Very high

- Can you drive?Usually, no

- DIY inspection:Possible

- DIY repairs:Mostly,impossible

- Price of repair:$300 - $650

- Commonreasons:Fuel pump, fuel filter, fuel lines, EVAP system, electrical problems

- How to fix:Check the pump, verify it has power, check the fuelfilter

Ignition Timing Issues

Ignition timing is one of the most important settings in a carburetor engine. It refers to the moment the spark strikes the piston at the top dead center. This makes sure that the spark plug ignites the fuel at the best time. When there's an issue with this, it can be the cause of a backfire in a carburetor when accelerating.

Aside from the backfiring effect through the carburetor while accelerating, ignition timing issues can be coupled with symptoms such as poor acceleration times and engine knock. These can be caused by a variety of factors, including incorrect spark plug gap, wrong spark plug heat range, or worn distributor points.

There are several possible solutions to ignition timing issues. One is to adjust the timing by advancing or retarding the distributor. This can be done by rotating the distributor body or by moving the spark plug wire to a different position on the distributor cap.

Another is to replace the spark plugs with ones that have the correct gap and heat range. To ensure that they have the right gap and heat range, it is best to consult the owner's manual that comes with your vehicle. You can also ask a qualified mechanic about this matter.

If the problem persists, it is likely that the distributor points are worn and need to be replaced. Distributor points are found in the ignition system. They work with the distributor cap and the spark plug wires to create sparks that ignite the fuel in the engine. If they are worn, it can cause problems with the ignition timing and lead to issues such as backfire and poor acceleration. The points can be replaced with either new ones or with an electronic ignition system.

When troubleshooting ignition timing issues, it is important to consult a qualified mechanic. They will be able to properly diagnose the problem and offer the best solution for your particular situation. Replacing parts or adjusting the timing on your own can be dangerous and may make the problem worse.

Lean Air/Fuel Mixture

A carburetor engine needs the right air/fuel mixture to run efficiently. If the mixture is too lean (not enough fuel in the mixture), the engine will run hot and may backfire when accelerating. A lean air/fuel mixture can also cause piston damage and spark plug fouling.

To diagnose a lean air/fuel mixture, start by checking for intake leaks. Next, check the carburetor float level and fuel pressure. If both of these are good, then the problem is likely with the carburetor itself.

There are several possible solutions to a lean air/fuel mixture. One is to adjust the carburetor float level. This is usually the first thing mechanics do to try to fix the issue. The needles and jets should also be checked for possible problems. The components should be recalibrated or replaced, whichever is the most appropriate course of action.

The needles and jets in a carburetor control the air/fuel mixture. The needles regulate the amount of fuel that is delivered to the engine, while the jets control the amount of air. If either of these parts is not working properly, it can cause the air/fuel mixture to be too rich or too lean.

Second, replace the carburetor. This is usually necessary if the float level cannot be adjusted or if there are other carburetor problems.

Third, you may need to install a larger carburetor. This is an option if you want more power from your engine.

Fourth, you may want to consider installing a fuel injection system. This is the best option if you want more power and reliability from your engine.

If you suspect a lean air/fuel mixture, the best thing to do is take your vehicle to a mechanic or tuning shop for diagnosis and repair. Do not try to adjust the carburetor yourself unless you are experienced with this type of work. Improperly adjusted carburetors can cause engine damage and may void your warranty.

Rich Air/Fuel Mixture

As mentioned earlier, when it comes to carburetor engines, one of the most important things to keep in mind is the air/fuel mixture. This mixture needs to be just right for the engine to run properly. If the mixture is too rich or too lean, it can cause a number of problems.

A rich air/fuel mixture is when there is too much fuel and not enough air. This can cause many issues, including backfiring when accelerating. This is basically the opposite of having a lean air/fuel mixture, which is a condition wherein there is too much air and not enough fuel. This can also cause several issues, including rough idling and poor acceleration.

If you're experiencing any of these problems, it's important to diagnose the issue and find the root cause. There are some possible remedies depending on the problem. In some cases, you may need to replace parts in your carburetor.

In some instances, you may need to replace parts in your carburetor in order to fix a rich air/fuel mixture. The most common parts that need to be replaced are the jets and the needles. If these are not working properly, it can cause the air/fuel mixture to be too rich or too lean.

Aside from these, you might also want to think about the other alternatives discussed in the previous item like replacing the carburetor itself if it is already prone to malfunction, getting a bigger unit, or installing a fuel injection system.

Whatever the issue, it's crucial to have it resolved as soon as possible. Otherwise, you could end up damaging your engine. If you're not sure how to diagnose or fix the problem, it's always best to consult with a mechanic or other expert.

Damaged Valve

When it comes to carburetor engines, the quality of the valves is extremely important. If there is a bent valve in a vehicle, it can cause all sorts of problems, including backfiring when accelerating. Fortunately, this rarely happens in an engine but it's definitely something that you should keep a lookout for due to its plethora of repercussions.

One possible cause of a bent valve is improper installation. If the valves are not installed correctly, they can become bent over time. Another possible cause is overheating. When the engine gets too hot, the metal of the valves can soften and warp. This can also happen if the engine is run without oil for too long or has lubrication issues brought about by too lean or rich air/fuel mixture.

If you suspect that your carburetor has a bent valve, there are several symptoms to look for in addition to the backfiring problem. First, the engine may run rough or misfire. Second, you may notice a decrease in power and acceleration.

If you suspect that your carburetor has a bent valve, the first thing you should do is check the installation. Make sure that the valves are installed correctly and that they're not warped or damaged. If everything looks good, then take the carburetor to a mechanic and have them inspect it thoroughly.

Once you've confirmed that the carburetor has a bent valve, there are several options for fixing the problem. The most common solution is to replace the affected valves. However, depending on the severity of the damage, it may be possible to simply straighten the valves. In either case, it's best to leave this job to a professional.

If you have a carburetor with a bent valve, don't ignore the problem. Not only will it result in decreased performance, but it can also cause serious damage to your engine. Be sure to check the installation and get the carburetor checked out by a mechanic as soon as possible.

Worn Valve Seals

Lastly, when a valve seal is worn, it can cause a backfire when accelerating with the carburetor. The backfire is caused by the leaking of air through the worn seal. This causes a lean mixture in the carburetor, which can lead to pre-ignition and engine knock.

To diagnose a worn valve seal, first, check for engine knock. If you hear an engine knock, it is likely that the valve seal is worn. Next, check the carburetor for a lean mixture. A lean mixture will cause the engine to run less efficiently and can lead to pre-ignition. Finally, check for leaks in the carburetor. If you notice any leaks, it is likely that the valve seal is worn.

To fix a worn valve seal, you will need to replace it. This can be accomplished by removing the damaged seal and replacing it. Make sure to use the proper size and type of seal for your engine. You may also need to replace the carburetor if it is damaged as a result.

Conclusion

As shown here, a backfire through the carburetor when accelerating can be a precursor of more serious problems. Therefore, it is something that definitely requires your immediate attention. Should you start experiencing this as well as other related symptoms, be sure to have your vehicle repaired as soon as possible.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment