Updated by Dmitry Sapko in January 2024

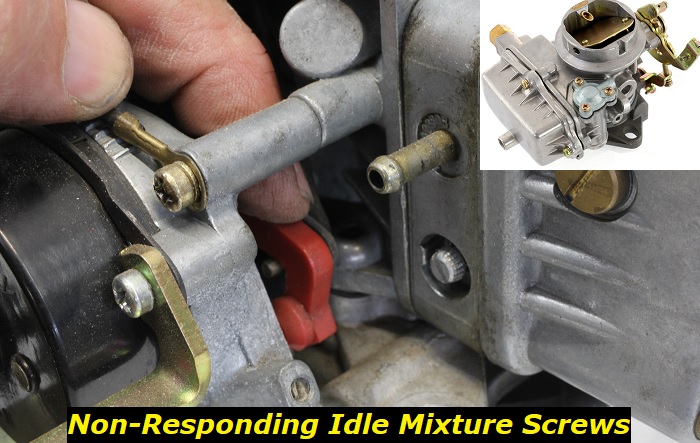

If your idle mixture screws don't do absolutely anything, there is a chance that the idle speed screw is too tightened now. You will need to set it to lowest available idle and then set the mixture screws. Also, there is a chance that the idle mixture screws don't respond because the air enters the carburetor somewhere else. You will need to make sure that all the seals and gaskets are OK and do their job.

Engine idling problems highlights

- Level of urgency:Low

- DIY inspection:Possible but may be complicated

- DIY repair:Sometimes, possible

- Cost of repair:$150 - $600

- Can you drive?Yes

- Commonreasons:IAC valve, throttle position sensor, MAF sensor, carb problems, fuel pressure issues, air supply problems

- Ways to fix:Adjusting the system or replacing the faulty sensor or another part thatis diagnosedto be bad

Overview of the Idle Screws and the Carburetor System

Your carburetor's task is to ensure the combustion chamber receives a balanced air-fuel mixture. The right balance is crucial to the engine's and car's performance. When the mixture contains too much air, it becomes lean. Hence, you risk damaging the engine. When the fuel outbalances the air, it becomes too rich. Your engine could flood, become smoky, stall, or waste fuel. The combustion chamber should receive a balanced air-fuel blend at a cold start, idling, or speeding.

You'll find your vehicle's carburetor between the air filter and intake manifold. So, the filtered air will flow through the carburetor and pass through a tiny or narrow throat (venturi). As it flows through the venturi, its pressure drops. The low pressure allows the fuel to spew from the fuel jet into the carburetor.

The fuel and air will form a perfect blend suited for the combustion chamber. The mixture will provide enough power to move your car. So, a big part of ensuring your car cruises smoothly on the road is keeping the carburetor in an operable condition.

All the components that aid the carburetor should work as expected.

The float chamber should consistently regulate the fuel in the carburetor. It does it through the help of a float that actuates the valve. It prevents a fuel flood from occurring.

The choke should ensure there is enough air in the carburetor. It does this by suppressing the air flowing into the carburetor. It will modify the intake manifold's pressure to allow fuel to trickle into the carburetor.

The throttle plate should constantly regulate the air-fuel mixture. The throttle plate opens when you activate the gas pedal to allow the more air-fuel mixture to flow into the combustion chamber. As you can tell, the throttle valve is movable to adjust the amount of the mix accessing the combustion room. The throttle plate nearly shuts when the engine is idle. Therefore, the plate restricts the mixture's flow with the help of idle mixture screws and an idle jet.

The idle mixture screws will prevent the throttle valve (butterfly valve) from shutting completely to let air into the carburetor at low RPM. The idle mixture screw stops working once the RPM increases.

Unresponsive Idle Mixture Screws

An unresponsive idle mixture screw often causes a very lean air-fuel mixture at low revolutions per minute. You'll notice that an adjustment doesn't solve the issue.

Apart from the lean mixture, an under-par throttle response increases idle speed. It may also force the engine to shut down during idle. One may assume that a simple screw turn can fix an unresponsive idle mixture.

Adjusting Idle Mixture Screws

Before fixing the throttle body or the carburetor, reposition the idle mixture screws. Do it as follows:

- Step 1: Warm the engine

Engage the park gears and let your engine run for five minutes. You need to work with a warm engine. It doesn't matter if you're working on your motorcycle, car, or AVT. Keep it running after it warms up.

You can observe how the adjustment influences the idle speed with a warm engine.

- Step 2: Find the carburetor

The carburetor is attached to the air filter.

- Step 3: Check the idle mixture screws' position

Turn the screws clockwise as you count the turns. Use a flathead screwdriver.

Stop the turns once the screws sit lightly. Do this for all the idle mixture screws. It's important to let them sit in the same position.

- Step 4: Tighten the screws until the engine sounds rough

Once they're in the same position, tighten them as you listen to the idling hums. Count the turns to ensure you balance all the turns. Stop turning when the sounds turn to rough rising and falling.

- Step 5: Untighten the idle mixture screw

Count as you listen to the sound. Stop once you hear revs instead of idle hums.

- Step 6: Tighten to the midpoint

Turn the screws clockwise and ensure they sit at the midpoint (where the engine doesn't sound rough or revs). Count the turns and adjust the other screw.

Too many clockwise turns will make the mixture lean at idle, while excess anticlockwise turns may result in a rich blend at low RPM.

Sometimes the idle mixture screw will need more than a screw turn because you may be dealing with unresponsive idle mixture screws.

What Causes Unresponsive Idle Mixture Screws

Idle mixture screws give you a fantastic low RPM performance. But this cannot happen if the screws don't nearly shut the throttle plate during idle. Here are some reasons why you're experiencing persistent unresponsive idle mixture screws.

- Vacuum Leaks

Vacuum leaks will cause the idle screws to effect no change as the car idles or drives at low RPM. A poor idle, engine stalling, and lean mix during idle are clear signs of vacuum leaks. The vacuum leaks will prevent the idle mixture screws from doing the job. More air than required during low RPM or while idling will pass through the throttle plate. Hence, the carburetor will deliver a lean mixture. Attempts to screw the idle mixture screws will not fix the air leak.

Fixing Vacuum Leaks

You may have to fix the vacuum leaks before readjusting the idle mixture screws. Begin by checking whether you have vacuum leaks in your carburetor.

You'll have to trace the leak to fix it. A carb cleaner will help you trace the leak. Spray the carb cleaner on the throttle body, gasket surfaces, or the base of the carburetor. It means you have a vacuum leak if the cleaner gets sucked or an increased idle. You can also hook a vacuum gauge at the base of the carburetor. You may have a vacuum leak if it reads below the recommended level.

Fixing the vacuum leak may entail replacing the manifold, vacuum hoses, or gasket.

Consider tightening the mounting bolts on the throttle body or the carburetor if you traced the leak to the throttle body or the carburetor. Tighten the intake manifold's bolt if it is the source of the leaks. You'll have to replace them if the problem persists.

- A High Float

The float level should always be correct for the idle mixture screw to operate as expected. You'll need to check the float settings if you're experiencing an unresponsive idle mixture screw.

You'll notice an off-idle stumble when the float level is too low. A low float level also causes a lean mixture during low RPM. You risk fuel flood and a rich blend if it's too high.

A high float may cause the insensitive idle mixture screw. Therefore, bend the float level to the correct level.

- Dirty Idle Air Bleed

The idle mixture screws need the idle air bleed to deliver enough air during low RPM. Therefore, you could be dealing with clogged or incorrect air bleed if the idle screws are not responding to the adjustment. Drivers and racers have traced loads of unresponsive idle mixture screws to clogged air bleeds.

Fix

Clogged idle air bleed will cause a rich mixture despite readjusting the idle screws. You'll need to unclog the idle air bleeds for a proper air-fuel blend during low RPM. Use carb cleaner to unblock the air bleeds.

Remove the idle air bleed and soak it in carb cleaner overnight. The overnight carb cleaner soak will unblock the air bleed. Blow it with compressed air to remove any remaining dirt before re-attaching it to the carburetor.

Also, check if there is a vacuum leak on the idle air bleed. If you observe vacuum leaks, tighten the idle air bleed screw. It should bottom out.

Wrapping Up

A screw turn may not fix an insensitive idle mixture screw if the problem lies beyond your screws. Other issues like vacuum leaks, the wrong float level, and clogged air bleeds may cause the screws to stop responding to any adjustment.

Therefore, assess the carburetor to locate the cause of the unresponsive idle mixture screws. You'll need to fix these issues before readjusting your screws for an undisturbed low RPM performance.

About the authors

The CarAraC research team is composed of seasoned auto mechanics and automotive industry professionals, including individuals with advanced degrees and certifications in their field. Our team members boast prestigious credentials, reflecting their extensive knowledge and skills. These qualifications include: IMI: Institute of the Motor Industry, ASE-Certified Master Automobile Technicians; Coventry University, Graduate of MA in Automotive Journalism; Politecnico di Torino, Italy, MS Automotive Engineering; Ss. Cyril and Methodius University in Skopje, Mechanical University in Skopje; TOC Automotive College; DHA Suffa University, Department of Mechanical Engineering

Add comment